Why Gravel Driveways are the Best Driveways

Up until now, gravel driveway technology has been relatively unevolved. Gravel driveways have been around for ages, and come with a few benefits as well as a plethora of problems. Asphalt and concrete have made better-looking driveways for a long time, however, that’s not the case anymore.

Thanks to companies like TRUEGRID, the gravel driveway is making a big comeback. If you’re a homeowner looking to install a new driveway, let’s go over a few of the many reasons why the modern gravel driveway of today is far superior to any other option you’ll find available to you.

Stabilized Gravel is the Best Driveway Material

Unstabilized gravel tends to migrate and become pulverized, which leads to bare spots, ruts, dust, erosion, and more. The right DIY driveway pavers will eliminate all of these problems at once.

TRUEGRID’s gravel pavers allow you to keep your gravel driveway firmly locked into place. They prevent all of the common gravel driveway problems from occurring while providing you with many other benefits as well.

Ease of Installation is Unparalleled

The benefits of gravel driveway pavers begin with the ease of installation. The typical driveway takes multiple days to install and perfect. TRUEGRID’s gravel pavers, however, allow you to complete the installation of your brand new driveway in as fast as one day. That means you can receive your driveway pavers in the morning and be ready to park your vehicle on them by sunset.

First, the driveway area may be excavated from 1 to 10 inches depending on your soil and stabilization needs. Then, a permeable landscape fabric is laid at the bottom and up the sides to block weeds and keep the separation of the soil and gravel layers. When needed the base rock is laid and rolled. Typically 6 to 10 inches of a drainage rock type base are used when stormwater detention and pervious cover credit is desired or when the soil is soft and needs stabilization. Road bases and other densely graded base materials can be used when extensive drainage is not needed, only load support. In some cases where the driveway already has a compacted gravel surface or is stable aggregate, then scraping the top layer, 1 to 2 inches may suffice. The gravel base is compacted with a roller or plate compactor.

Once the base is compacted and level, the gravel driveway pavers are locked into place over the top of it. After that, a fill gravel is poured and spread filling to the top of the grids. Good gravel fills are angular (no rounded), hard, uniform size (1/2″ to 5/8″) and clean. These fills will provide great drainage and resist erosion and migration. Some alternative fills may require compaction into the paver with a roller or plate compactor. That’s the entire process in a nutshell. Pretty simple, right?

Another benefit of the gravel driveway pavers from TRUEGRID is the eco-friendliness of the material. In a world where the climate crisis is coming to a head, TRUEGRID has made the effort to ensure maximum eco-friendliness of their products through production and installation.

100% post-consumer recycled plastic products and no heavy equipment required make the driveway pavers from TRUEGRID the single most environmentally-friendly driveway product on the market. Allowing rainwater to infiltrate through the surface into the soil helps keep local waterways clear of auto pollutants and nasty runoff.

Permeability is a Plus

In addition to being easy to install, TRUEGRID permeable paver will greatly reduce any chance of flooding or erosion. Since they are 100% permeable, even the heaviest of rainfalls will simply drain right through your driveway and directly into the soil beneath.

This prevents unnatural water displacement and keeps your driveway in perfect harmony with nature. If you’ve ever had to deal with a flooded-out driveway, you know that prevention is the wisest route to solving flooding problems.

Your Style Won’t Suffer

The aesthetic of a gravel driveway is nearly unmatched. Aside from gravel, you can choose from a wide variety of aggregate for your driveway. Limestone, blackstar, chipped granite — any type of angular gravel will work. Even if you’re in the middle of the suburbs, this affords you unmatched stylistic diversity, color choices, and unique charm.

If you want to stand out from the crowd or if your house would look better without an asphalt driveway, there’s no better way to mix it up and introduce some natural beauty to your home than with gravel driveway pavers.

It’s Time to Make the Switch to a Gravel Driveway

Now that gravel driveways have evolved, there’s really no excuse not experiment with a gravel driveway, especially with permeable pavers from TRUEGRID to build with, there’s never been a better time to install a gravel driveway.

You can easily and quickly install a new driveway in under a day’s time. It’s so simple, you can even let your family pitch in and help.

Asphalt and concrete require regular maintenance to stay in pristine shape, but due to the incredibly durable nature of a driveway built with gravel pavers, you can enjoy your driveway for decades to come without overwhelming you with maintenance costs and consuming large amounts of time.

If you want a uniquely beautiful and durable driveway that will never flood, erode, or degrade over time, you couldn’t ask for a better solution than TRUEGRID’s gravel permeable pavers.

As a commercial business, you need a parking lot for a few reasons. Not only does a parking lot give your employees, customers, and visitors a place to comfortably park their vehicles, it adds an element of professionalism to your building as well. However, most parking lots require a permit to build.

If you’re a small business without much traffic, even a small, unstabilized gravel lot requires a permit to excavate and install. Chances are you need something more permanent for your employees and visitors to park on if you get moderate or frequent traffic. There are, however, a couple of ways you can implement a professional, durable parking lot without having to obtain a permit of any kind.

If you are looking to lay a semi-permanent or permanent parking lot for your commercial business, here’s how you can circumvent almost all of the common requirements without sacrificing anything in the way of durability, functionality, or aesthetic appeal.

The Parking Lot Building Process

Due to the impermeable nature of both concrete and asphalt, cities require special permits before you can build a parking lot made from either of these materials.

If you hire a contractor to pave your parking lot, as most business owners do, that company needs to submit paving plans for review and approval prior to actually beginning the installation process.

These permits and code restrictions protections aren’t without good reason. They help protect the community from overdevelopment and flooding. However, for the average business owner looking to quickly install a parking lot, they can be quite a hassle.

Every construction company must apply and wait for their applications to be approved before beginning work on your parking lot. This can eat up valuable time and affect your bottom line.

How to Circumvent the Need for Parking Lot Permits

With almost any type of material you want to use for your parking lot, some kind of permit is going to be required before you can start building it. This includes concrete, asphalt and gravel-only. But, what if there was a way to create a permanent lot with durable, high-quality materials without having to apply for any type of permits, no matter your location? Thankfully, on many sites there is.

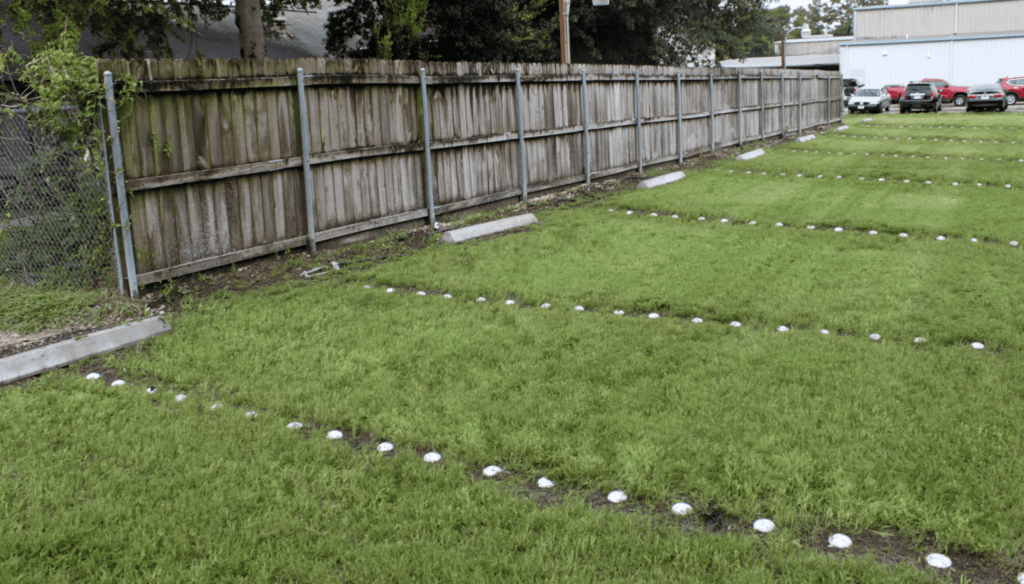

If you have existing grass, it can be stabilized with a unique paving product to park on without disturbing the natural hydrology of the site. When the hydrology is changed — when the site becomes more impervious — that is when the city requires added stormwater detention and drainage. But if you can create a parking lot without changing the site’s hydrology, then you can pave without permitting. How is this possible, you might ask? Well, there’s a simple workaround you can use, provided you have the right products and the right site conditions.

As it stands, there are only two ways to pave without a permit for commercial purposes. You can either use the TRUEGRID ROOT system to stabilize existing grass on your property or you can use TRUEGRID PRO PLUS to upgrade an already existing gravel lot.

If there is excavation involved in your parking lot installation process, you’ll need a permit in most cases. However, if you are simply adding plastic pavers to existing grass, or adding plastic pavers to stabilize an already existing gravel lot, this can be done without any additional permits required. Permeable paving technology has evolved to the point where you can park commercial traffic on grass or stabilized gravel. Assuming you’re working with an unstabilized gravel lot that is already in place, or an undisturbed grass lot, the installation process is very simple.

Installing the TRUEGRID ROOT System

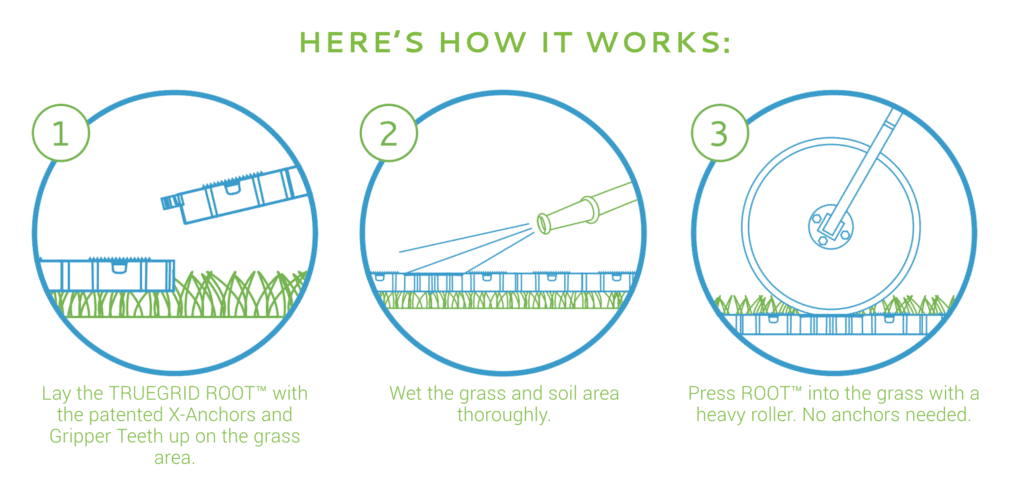

For example, TRUEGRID ROOT pavers can be added to any plot of land with grass on it. For a grass lot, the TRUEGRID ROOT system uses interlocking pavers that are quickly and easily laid over the level surface of grass. The grass is mowed short, then the area should be thoroughly wet. The pavers are then laid on the grass and pressed into the surface with a heavy or vibrating roller or vehicle. The pavers are then compacted into the ground by driving over them and the parking lot is complete.

The system allows grass to grow through the paver cells and stabilize the area for vehicle traffic without changing the hydrology, drainage or even the natural grass appearance of the site.

Installing TRUEGRID PRO PLUS Pavers

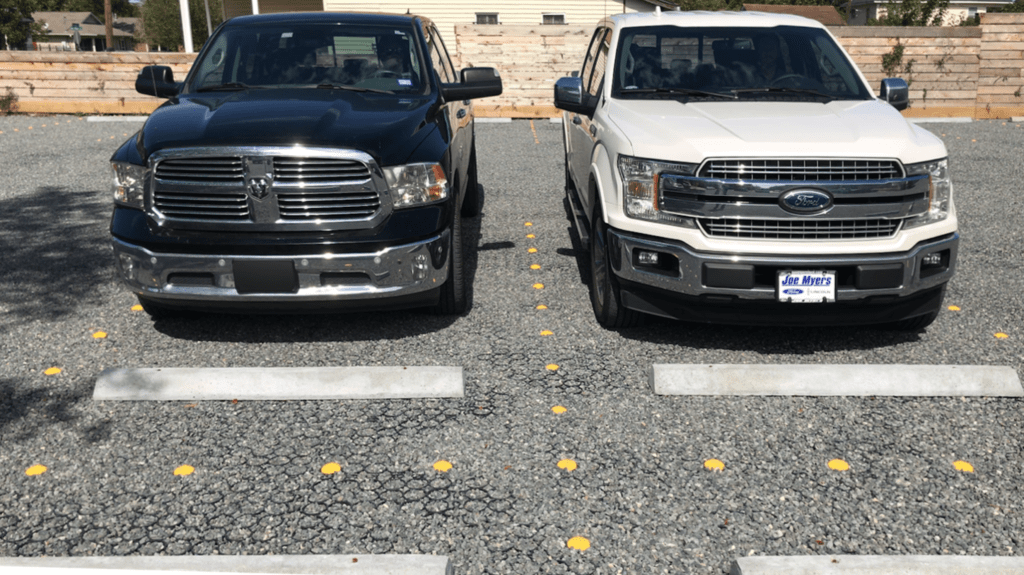

An existing gravel lot consisting of loose gravel is a major headache for a business owner. Ruts, mud and dust come with gravel-only lots. There is a one-time solution that doesn’t need permitting as no impervious cover is being added.

The TRUEGRID PRO PLUS pavers would simply be installed over the top of the loose gravel after it has been compacted and leveled, with more gravel filled in the cells of the pavers. This provides a stabilized gravel lot that will not compact further and become impervious. Again, in this application, the hydrology of the site has not been changed and no impervious cover has been added.

The Two Best Methods of Permit-Free Paving

In these applications, the process of installing either the TRUEGRID ROOT system or the TRUEGRID PRO PLUS pavers is quick and painless and doesn’t require any additional drainage or maintenance once it’s complete.

This means you won’t have to worry about resurfacing your parking lot, resealing it, repainting it, or performing any of the common maintenance that asphalt and concrete lots require. Both the TRUEGRID ROOT system and TRUEGRID PRO PLUS are low-maintenance and eco-friendly.

All the Benefits of Asphalt and Concrete with None of the Hassle

If you want to install a durable, long-lasting, stylish, permeable, and versatile parking lot in less than half the time it would take you to lay an asphalt or concrete lot, you should install a permeable paver lot. Whether you’re using the TRUEGRID ROOT system for grass or TRUEGRID PRO PLUS pavers for stabilizing gravel, either type of lot will cost you far less, require almost zero maintenance, and last for decades.

Especially if you’re in a position where you can’t afford to or don’t want to go through the hassle of obtaining a special permit, both the TRUEGRID PRO PLUS pavers and the TRUEGRID ROOT system can help you install a parking lot without these requirements. If you’re working with an already existing gravel lot that is unstabilized, or you want to lay a quick parking lot over plain grass, these products are the only way you can pave without a permit.

If you were to take a tour of every parking lot in America, you’d find that while most of them are made from concrete or asphalt, there is a very large portion of parking lots built from gravel.

Gravel lots serve a very important purpose, mostly that they are the cheapest parking solution you’ll find anywhere. Unstabilized gravel lots, in particular, are the fastest to install and with minimal costs upfront.

For lot owners trying to save some money or who only need a lot for a certain period of time, gravel can be the perfect solution. The shortest-lived gravel lots still come with a variety of additional maintenance issues, however, that you won’t find with asphalt, concrete, or properly stabilized gravel lots.

In case you own a gravel parking lot and you want to know how to quickly and cheaply transform it into a long-lasting lot which never requires any of the typical maintenance that gravel so often does, let’s take a look at how that can happen.

The Hassle of Maintaining Gravel

A gravel lot without any type of stabilization usually consists of a single-layer border around the entire lot. This border helps to generally keep the gravel from instantly spreading out and becoming unusable the moment somebody drives on it.

What many lot owners come to realize is that the border doesn’t completely prevent the migration of gravel. Bare spots can still develop as gravel is displaced, leading to ruts, mudholes, and an all-around ugly situation for anyone trying to park their vehicle.

Another common problem with gravel parking lots is the buildup of dust. As vehicles continue to drive over and pulverize your unstabilized gravel, the gravel particles keep getting smaller and smaller until they become dust. This dust builds up rather quickly and causes a myriad of problems for you and your patrons.

Dust buildup sticks to vehicles, making the need for a carwash come that much quicker for whoever uses your lot. Not only this, but dust buildup in gravel lots can be kicked up as people come and go, causing air pollution and triggering allergies for anyone sensitive to it. This choking hazard is one of the worst effects of using an unstabilized gravel lot.

Gravel lot owners have tried to combat these problems in a number of ways. The spread of gravel is usually fixed by bringing in more gravel and leveling out the lot. While still relatively inexpensive, this needs to be done frequently. As far as dust goes, the only way to really deal with it is to constantly spray water on your lot, wetting down the dust and preventing it from being kicked up.

Not only does this leave you with a partially muddy lot, but the water also dries out nearly instantly on hot days. You can see how this is not a very effective solution and leads to much more hassle than it’s worth to maintain a gravel parking lot.

The Solution to Gravel Parking Lot Dust and Bare Spots

The only way to eliminate both of these problems at the same time is to use a gravel lot stabilizer. TRUEGRID is one example of a company that offers permeable pavers designed to keep your gravel firmly locked in place and prevents it from being pulverized by traffic.

A gravel lot stabilized with TRUEGRID pavers features an interlocking layer of highly-durable plastic grids placed over the bulk of your gravel. Most of your gravel will be laid into an excavated area and covered with these pavers, while another layer of gravel is pressed into the top of the grids by a heavy vehicle. These grids lock the gravel into place, preventing dust buildup and gravel migration.

By implementing these cost-effective, eco-friendly, permeable pavers, you can eliminate the need for constant gravel lot maintenance. Not only that, but the pavers are incredibly quick and easy to take apart, making their installation and deconstruction the work of about 1 full day, if not less.

TRUEGRID Pavers Make Gravel Parking Lot Maintenance Effortless

With all the benefits that TRUEGRID gravel stabilizing pavers provide, it’s no wonder that gravel lot owners all across the nation are making the switch. With all of the durability of asphalt and concrete, and none of the problems associated with asphalt, concrete, or unstabilized gravel, a permeable paver gravel lot is the best parking lot you could use.

Not only are there plenty of aesthetic options for style’s sake, the eco-friendliness, cost-effectiveness, quick install time, and almost zero maintenance requirements of these pavers make choosing TRUEGRID’s pavers for your gravel parking lot an absolute no-brainer.

Added bonus: in most areas, grid- stabilized gravel lots are coded as pervious cover, where gravel alone is considered impervious and may require detention or drainage systems. This is a great workaround for anyone considering a hassle-free parking area. Invest in Truegrid paving today.

Gravel parking lots aren’t the most common type of parking lot you’ll find adjacent to most businesses, but they are practical in some scenarios. Gravel parking lots are typically cheaper than asphalt or concrete parking lots, making them a popular choice for smaller businesses or temporary parking solutions.

One of the biggest drawbacks of using gravel to build a parking lot, however, is the fact that they are incredibly prone to failing and need constant maintenance if built as a gravel-only lot without a stabilizing system to keep the gravel in place.

Other drawbacks are the mud, ruts, or dust that are come with weather and traffic.

In case you’re a business owner or someone tasked with maintaining a parking lot made of gravel, let’s go over the single most effective way to eliminate the chance of catastrophic gravel parking lot failure and constant maintenance.

Setting Up Your Commercial Gravel Parking Lot for Success

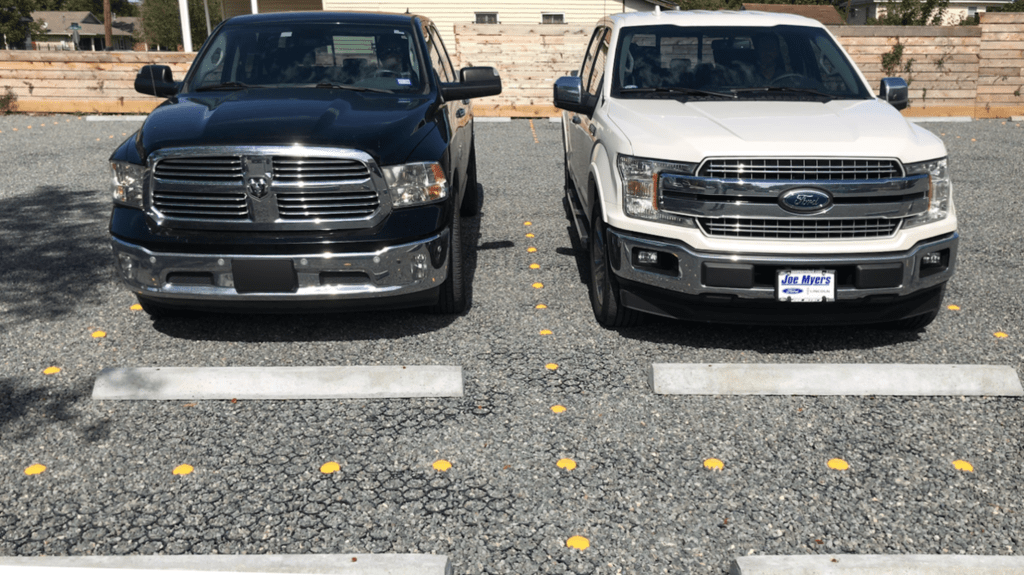

Commercial parking lots have a heavier burden to bear than parking lots for smaller, more residential-type businesses on average. The amount of traffic and abuse they need to be able to withstand is much greater, which is why any commercial gravel parking lot is guaranteed to fail without the right gravel stabilization.

Gravel alone is loose by nature, and not held together with any type of adhesive the way concrete and asphalt parking lots are. A commercial gravel parking lot without gravel pavers can function well for a little while, but will eventually begin to spread and disperse and the gravel migrates under constant pressure from turning wheels and walking feet. In wet weather that means mud, ruts, and puddles. In dry climates that means compacted gravel and dust.

You might think that makes gravel a totally impractical material for use in a commercial parking lot, but that isn’t the case. With gravel pavers like the ones produced by TRUEGRID, any commercial business can easily maintain a functional, high-performing gravel parking lot for many years without a problem.

How to Stabilize Your Gravel Parking Lot with Grid Gravel Stabilizers

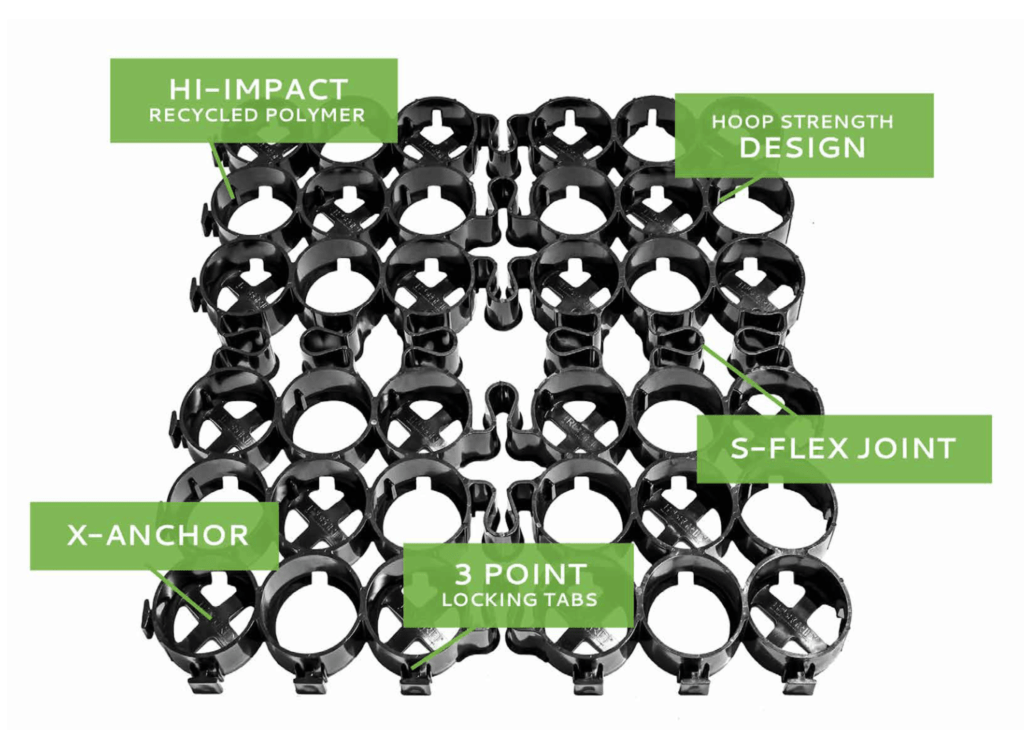

The only way to ensure a commercial gravel parking lot lasts as long as concrete is to stabilize it with a grid. The pavers from TRUEGRID are the best example of this type of grid. This patented interlocking gravel stabilization grid is comprised of super strong 1.8” deep cylinders groupings linked together by unique flex joints. When filled with gravel, the grid system has greater compressive strength than concrete and sufficient flexibility to never crack like asphalt or concrete. The grid cells keep the gravel in-place so maintenance or refilling of gravel.

There are other methods for gravel stabilization such as borders and webbing, but they don’t work well in commercial use when it comes to preventing the wear and tear of gravel due to traffic which leads to dust and ruts.

TRUEGRID pavers are the only product that prevents all of these problems. Due to its unique design, it eliminates the need for gravel refills and the frequent maintenance required with other stabilizing methods.

Unique Benefits of TRUEGRID Pavers

The patented 100 % permeable design of TRUEGRID gravel stabilizer allows for the effortless prevention of flooding, runoff, and erosion so commonly found in other gravel parking lots. The permeable nature of the gravel stabilizing pavers allows rainwater and runoff to drain directly through the grid and into the soil beneath where it can naturally be filtered, detained and released slowly in natural aquifers recharge.

Another major benefit of using a gravel stabilizer grid system from TRUEGRID is the elimination of the “heat island” effect we see so often in other parking lots. This is caused by hardscape parking lots that absorb the sun’s heat and don’t allow surrounding air to freely circulate, which leads to uncomfortably hot situations for customers and employees during the hotter parts of the year.

The gravel-filled permeable pavers have 40 % void or air space which eliminates this effect and does not allow heat to sit and accumulate directly over your parking lot.

Who Benefits Most from Gravel Stabilization Grids?

If you’re a business owner considering implementing a gravel stabilizer grid for your parking lot, there are some additional benefits to having a permeable gravel lot.

If you get heavy traffic in your gravel parking lot, want to prevent flooding, erosion, and heat islands, or you want to spend virtually nothing on parking lot maintenance for decades to come, then permeable pavers from TRUEGRID might be for you.

If you have crops, livestock, or nearby residents that might suffer from the dangerous clouds of dust from unstabilized gravel lots, a gravel stabilization grid is perfect for you. Preventing the pulverization and compaction of gravel with this commercial-grade grid system eliminates dust and allows natural water flow and infiltration at over 1000 inches per hour. All these help protect your local environment and can save money and headaches.

Finally, if you’re environmentally-minded at all, you won’t find a more eco-friendly parking lot material than the permeable pavers from TRUEGRID. They are made from 100% post-consumer recycled plastic, and every step along the way is optimized for maximum environmental friendliness.

From production methods through installation, these grids are the easiest to install, most cost-effective, and the smallest negative impact of any parking lot material out there. The TRUEGRID system actually has a positive effect on helping filter pollutants. TRUEGRID pavers are the number one choice for maintaining a gravel parking lot successfully for many years. Learn more about our product lineup here.