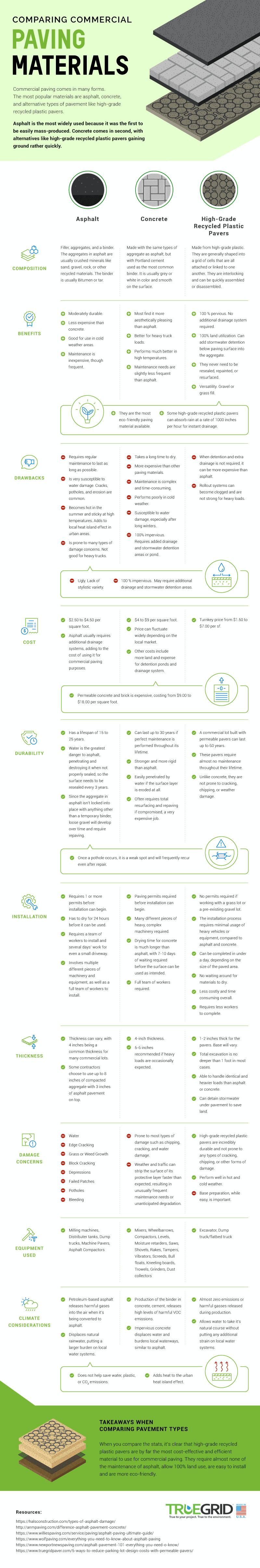

Infographic: Comparing Commercial Paving Materials

The ability to hold heavy loads is critical for any commercial paving project. Luckily, there are three commercial paving materials options to choose from when designing your lot: Asphalt, Concrete, and High-Grade Recycled Plastic Pavers filled with gravel or grass. It’s no secret that asphalt is the most widely used paving material, but why is that? And is it actually the best? Different materials might actually be best suited for different projects, depending on what your goals and objectives are. Maintenance, installation, drainage, cost, and necessary equipment are all things to consider when selecting a commercial paving material.

So which material is the cheapest? Which material lasts the longest? And which material comes out on top, overall? If you want to learn the answers to these questions and more, then look no further than the infographic below.

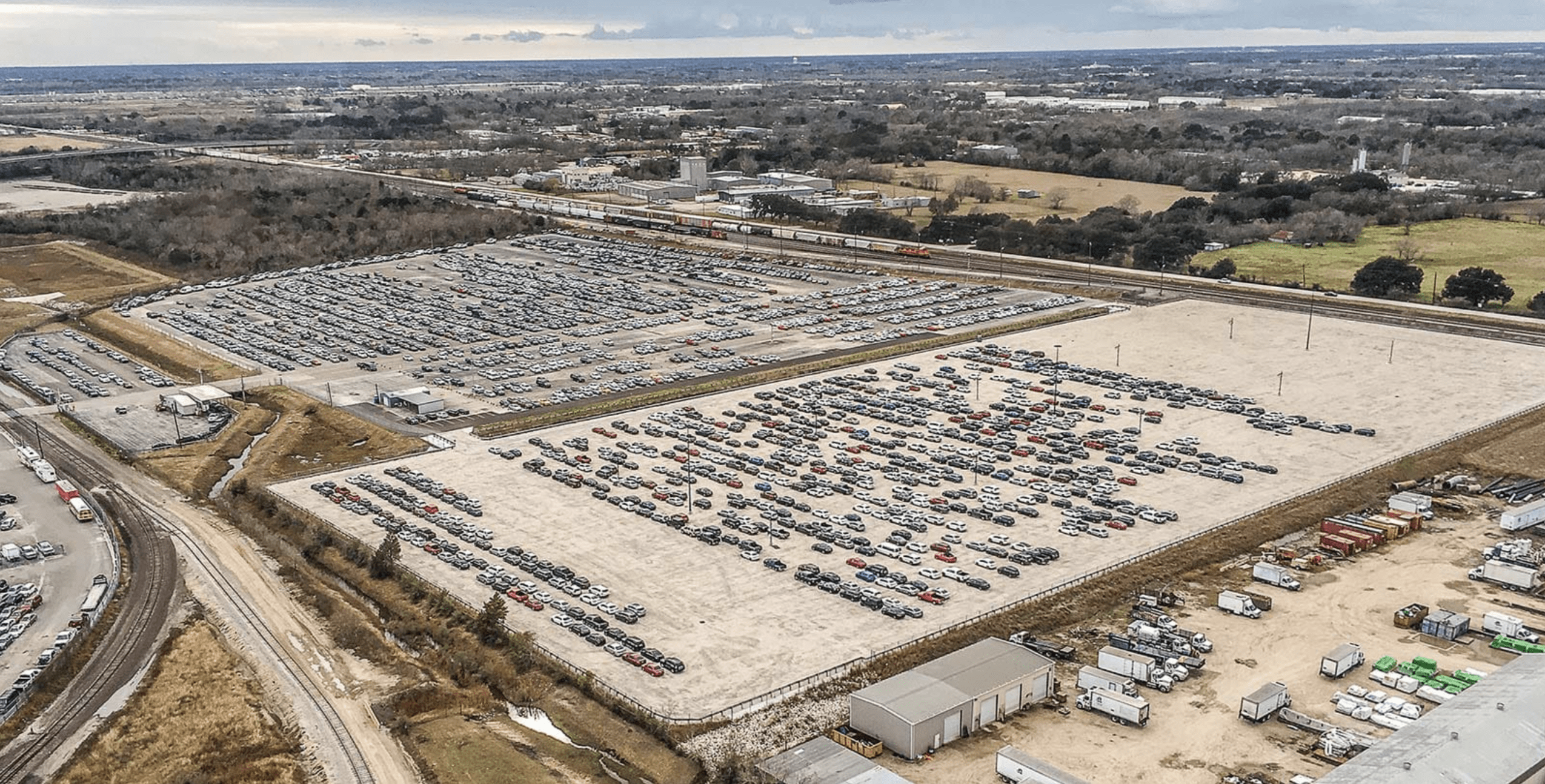

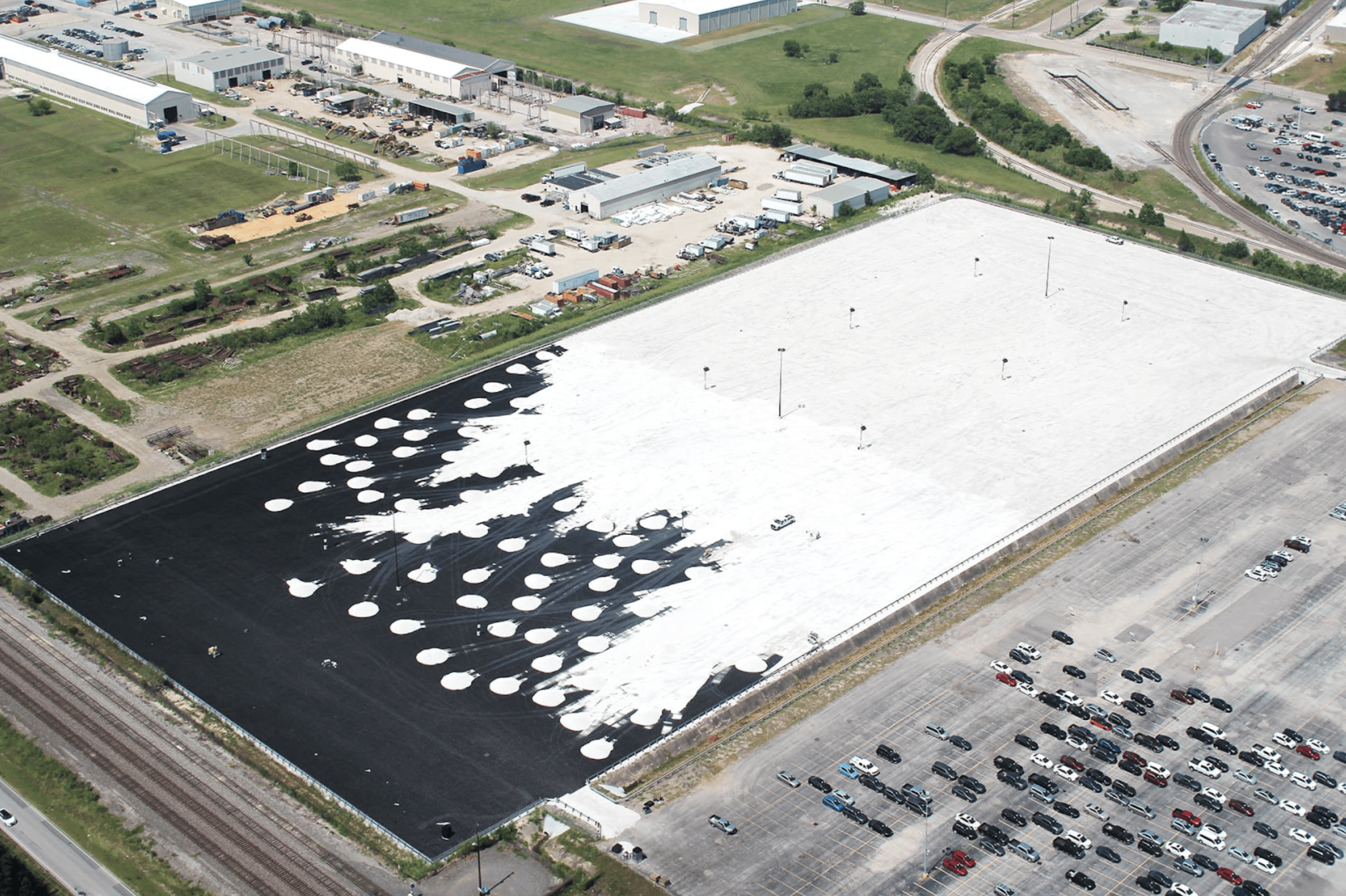

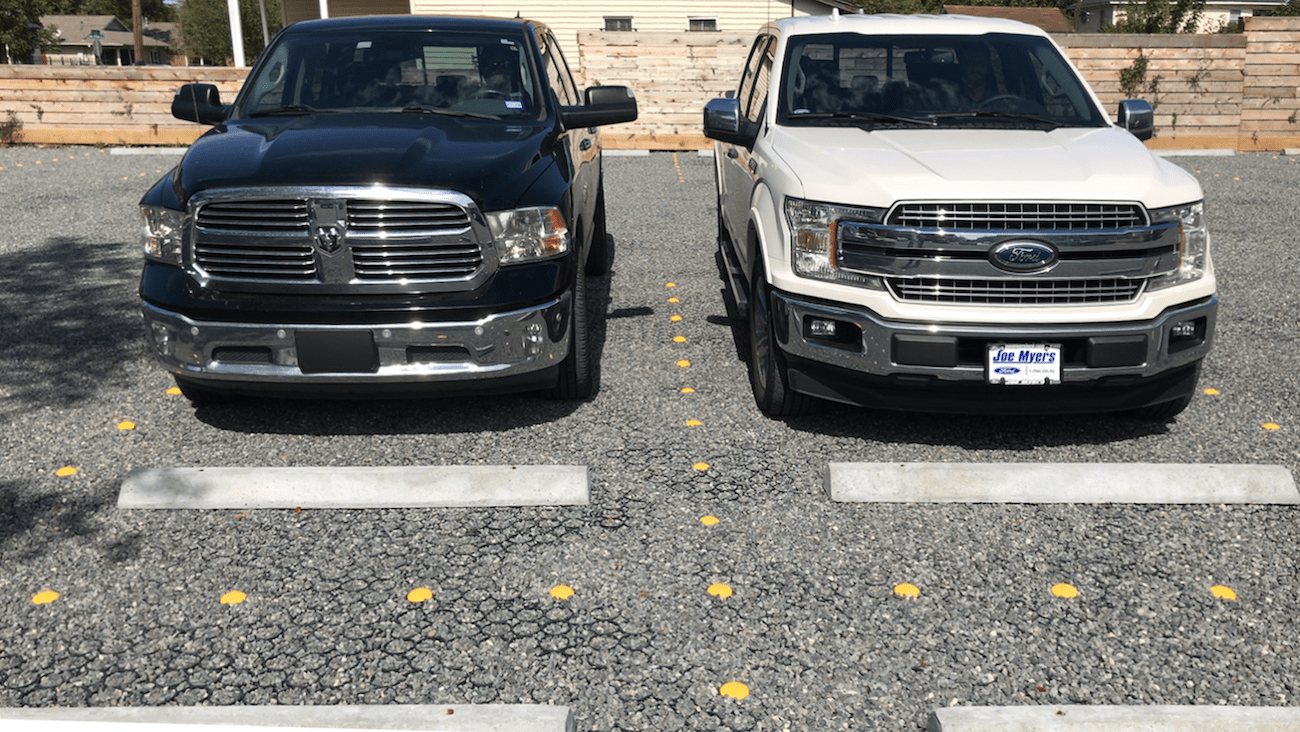

In Houston, Texas, the Cox Automotive Group needed a large car and truck inventory lot for auto auctions for commercial dealerships. It had already purchased the land for a 653,400 square foot concrete parking lot, 4 acres of which was to be designated as a detention pond. The plan was to install impervious concrete and use the detention pond to manage stormwater runoff.

However, when Cox learned it would need the extra 4 acres for additional parking spots, a solution was needed that could not only provide extra parking spaces but also manage stormwater without requiring additional land.

This might sound impossible at a glance, but thankfully, TRUEGRID was able to knock this project out of the park.

Building the World’s Largest Permeable Parking Lot

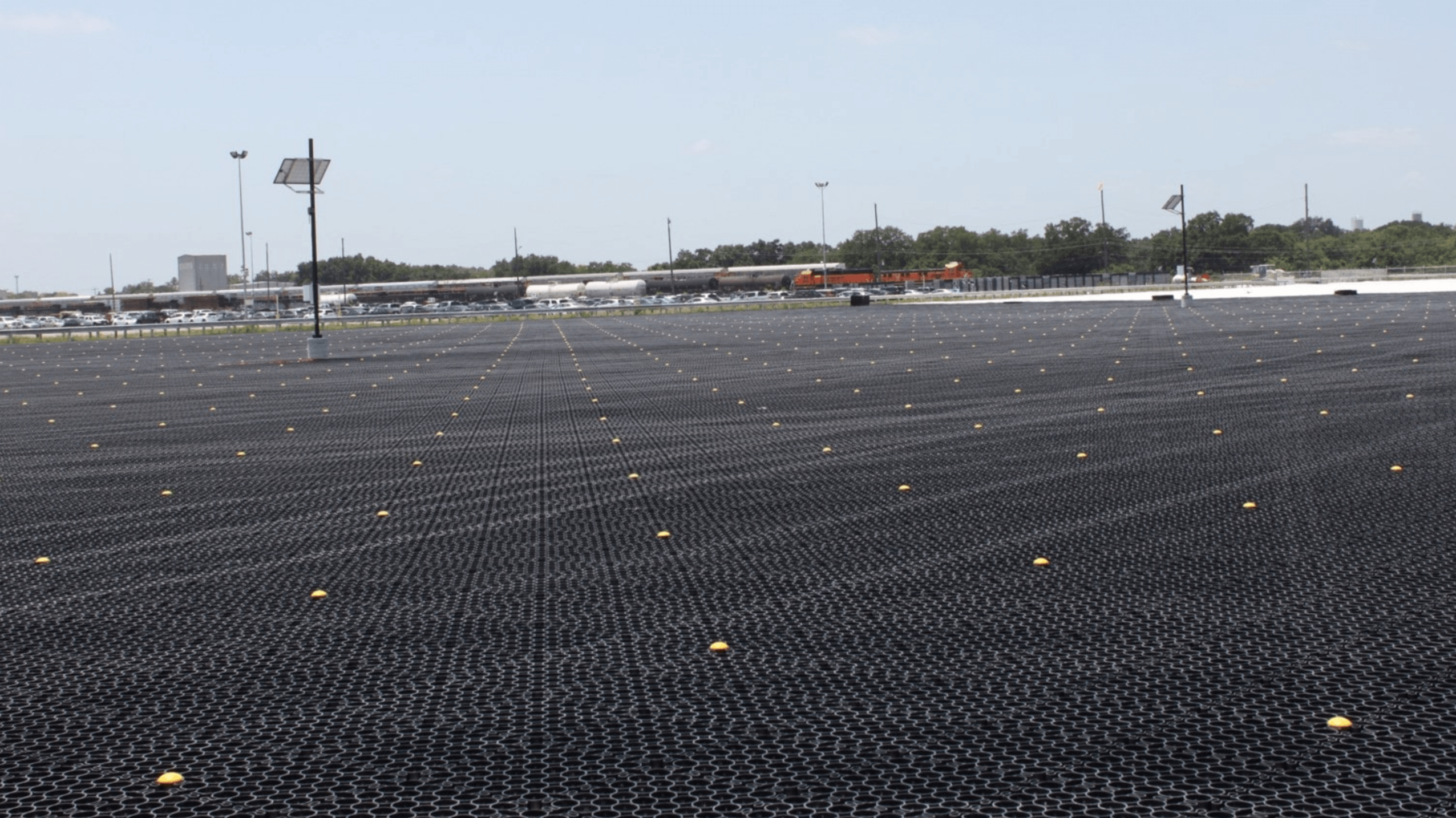

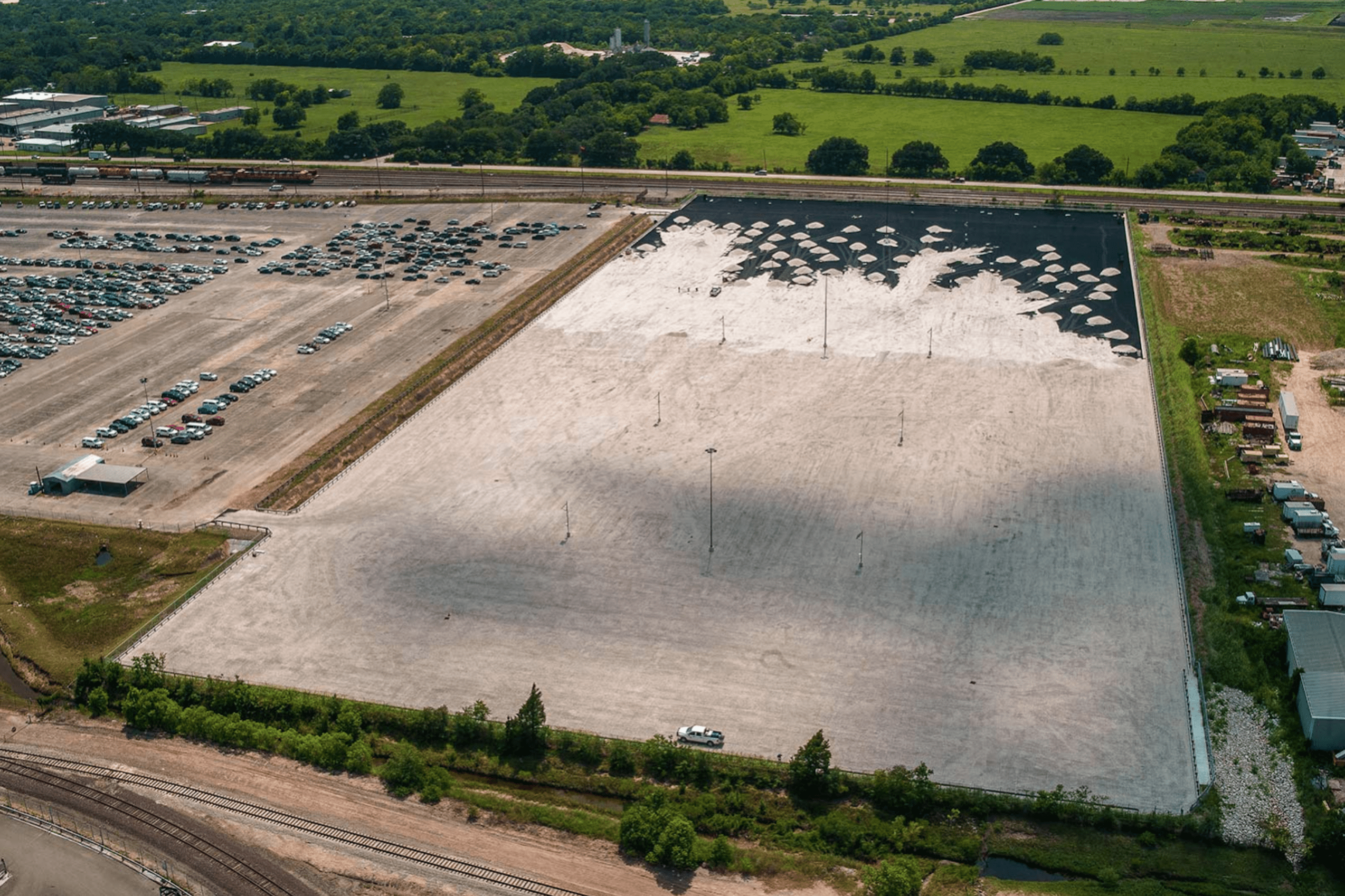

Other permeable parking lots have existed before this one, like the one TRUEGRID did for another well-known auto brand AutoNation, but TRUEGRID broke the world record on this project for Cox. By installing the 653,400 square feet of space with TRUEGRID PRO PLUS pervious pavers and clean limestone, TRUEGRID was able to meet every single one of Cox’ requests while providing a ton of additional benefits in the process.

The installation was simple and involved the excavation of the lot at about 10 inches in depth. The fat clay subgrade beneath the base was sloped to facilitate the draining of stormwater into a perforated pipe that could transfer the water directly to the city system in less than 48 hours.

Cox chose clean limestone as this was the least expensive aggregate locally available. The base was built with #57 stone limestone, and the fill material for the surface pavers was also limestone. The result was left a 100% permeable parking lot, a sprawling 15 acres in size.

How Did this Permeable Parking Lot Benefit AutoNation?

Cox Automotive was able to reap a variety of benefits from building its parking lot with TRUEGRID permeable pavers rather than with concrete. The main benefit was the elimination of the need for a detention pond. They were able to turn the additional 4 acres – which would have been an expensive concrete hole in the ground i.e. detention pond- into a usable extra 1,000 parking spaces, resulting in the potential for much more profit from this lot.

They were also able to save money and time. To install a concrete parking lot of this size would have taken a very long time, but with TRUEGRID products, that installation time was slashed and the parking lot was ready for use in just 10 weeks.

Cox was also able to save a ridiculous amount of money by using permeable pavers instead of concrete. These savings came in the form of a lower upfront cost, a lower installation cost, and the elimination of long-term maintenance fees as well. The use of TRUEGRID SuperSpot markers instead of painted lot lines was able to aid in these savings.

In an area known for times of heavy rains and flooding, this parking lot instantly drains up to 1000 inches of rain per hour with absolutely no runoff.

What is the Environmental Impact of a Permeable Parking Lot this Large?

The positive environmental impact of this project was massive. By using 100% recycled plastic pavers, TRUEGRID recycled 862,488 lbs of plastic. This is equal to over 6.5 million plastic gallon jugs.

Also saved were 3,942 tons of Co2, equal to planting over 829,933 trees. The stormwater this lot can detain is equivalent to almost 40,000 full-size bathtubs of water, easing what would have been a titanic strain on the local city water system.

What Can We Take Away from this Project?

This project might be the largest permeable parking lot in the world, but it’s just one example of what’s possible when you swap out impervious parking lots for permeable ones made with TRUEGRID pavers.

We’ve never before seen an innovation in any industry that can unilaterally save business owners both money and time while outperforming its competitors and predecessors AND having a much more positive impact on the environment.

The benefits from TRUEGRID pavement in both a personal, financial sense, and a communal, environmental sense are entirely new. The excitement around this innovative pavement solution is bound to grow exponentially over the next few decades, leading to more efficient pavement and a sizable dent in global emissions and waste. It’s safe to say that when it comes to innovating in an eco-friendly manner that benefits everyone, TRUEGRID is leading the way in pavement solutions.

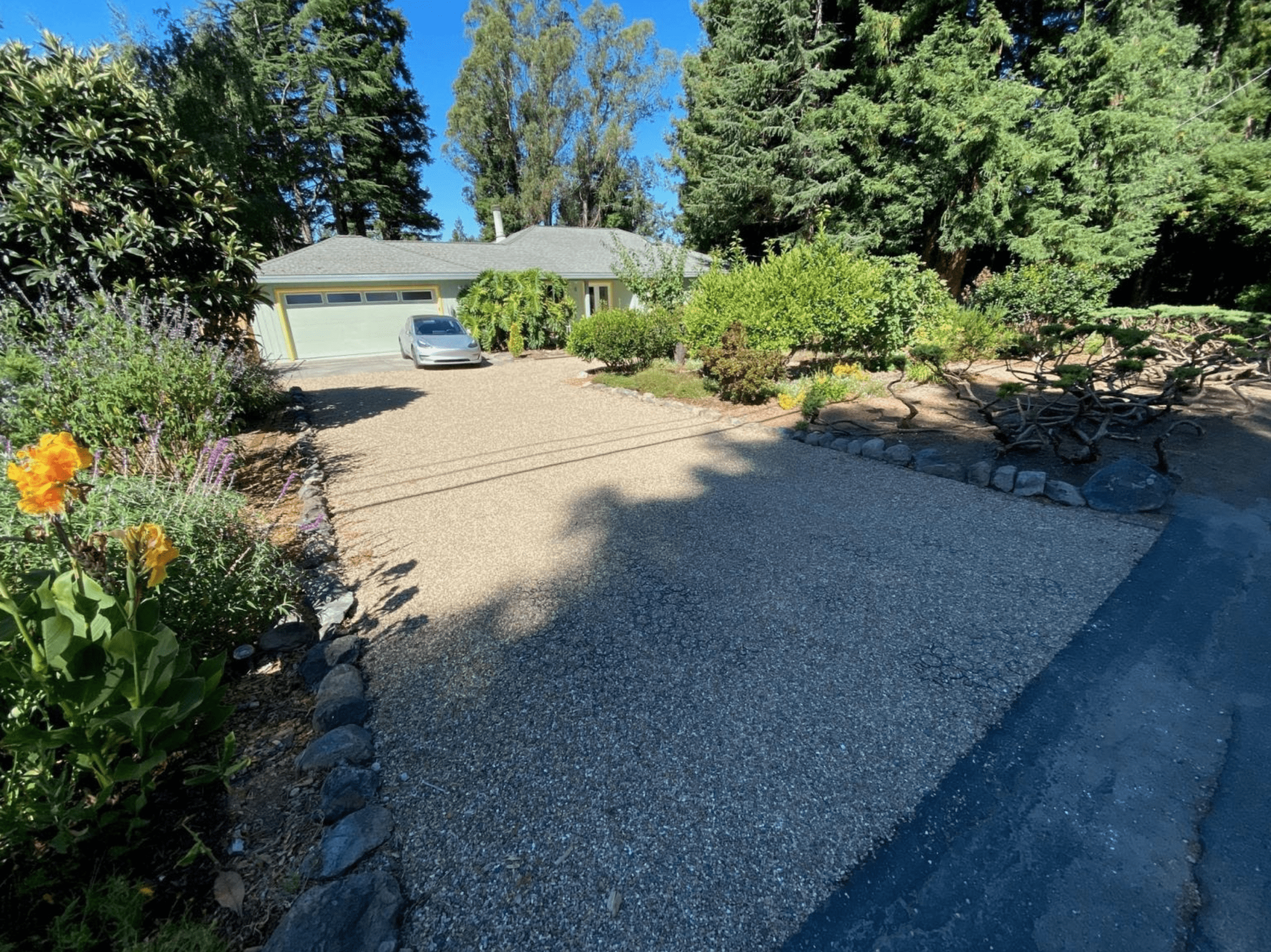

If you’re like many homeowners, you live in a home with a premade driveway, probably built without any input from you, so it might not fit your needs exactly. Maybe you’ve purchased another vehicle; you have someone new living with you, or you have some extra toys that need a place to sit.

For whatever reason, you want to extend your driveway, but it’s not within your budget to extend or widen it with asphalt or concrete.

Can you still extend a driveway if you can’t afford to use uniform materials? The answer is yes. Let’s go over the cheapest way to extend a driveway without breaking the bank.

Alternatives to Concrete and Asphalt

The biggest question you need to answer is what material to use to build your driveway if you can’t afford to have asphalt or concrete poured.

Plain, unstabilized gravel is the cheapest way to extend your driveway but won’t be very effective in the long-term. Unstabilized gravel will spread and become pulverized rather quickly, leading to ruts, mud, and dust that you wouldn’t want to deal with.

Installing stabilized gravel with permeable pavers, however, is the single cheapest and most effective solution to extending a driveway while providing long-term durability and functionality. TRUEGRID offers every type of paver you need to match your driveway situation.

These permeable pavers are made from 100% recycled plastic and can be installed so that they almost seamlessly blend into or alongside your current driveway. Even if your driveway is asphalt or concrete, you can extend it effortlessly with TRUEGRID’s permeable pavers.

How to Extend a Driveway with Permeable Pavers

The process is insanely simple and can even be done in DIY fashion. First, you measure your intended expansion area and order enough pavers to fit accordingly.

If your driveway doesn’t match the shape of the permeable paver grids exactly, these grids can be easily trimmed to fit your expansion area.

Next, the intended area is excavated to a depth of approx. 9 inches, depending on your preference. If you have compacted gravel and are not looking for more drainage, as little as 2 inches of excavation may be needed.

Then, a thin cloth is laid at the bottom of the excavated area to block weed growth from below. Gravel, limestone, or an angular aggregate of your choice is poured into the excavated area and compacted. The permeable pavers are then laid over the top and easily snapped into place.

After that, the pavers are filled and rolled with more aggregate, creating a level, solid surface. Use fill aggregate that complements your home and landscaping.That’s the entire process in a nutshell. It’s so simple and quick you can complete it in a single day.

The Benefits of TRUEGRID Pavers Over Other Materials

TRUEGRID’s pavers can be significantly less expensive than concrete pavers or brick pavers. TRUEGRID can be filled with grass or gravel to create a more natural aesthetic and add more drainage than asphalt, concrete, or other hardscape pavers. Made from highly-durable, 100% recycled plastic, these pavers can reduce upfront cost, overall maintenance, as well as installation.

If you extend your driveway with TRUEGRID pavers, it will also be permeable and protected from flooding. This is perfect for sloping driveways or driveways in a flood zone because the water drains right through the pavers and into the soil. TRUEGRID also offers erosion protection.

In addition to providing these benefits, TRUEGRID takes the utmost care to ensure that its products are tops in eco-friendliness. From production to installation, their products are designed to benefit the environment as much as possible. In addition to using and repurposing recycled plastic, TRUEGRID acts as a natural stormwater filter to allow infiltration and bioremediation to remove pollutants before they recharge our aquifers. There are no toxic sealants needed and the carbon footprint is a fraction of other paving alternatives. For this reason, you might prefer to extend your driveway with these pavers rather than asphalt or concrete.

Pavers are the Most Cost-Effective Way to Extend Your Driveway

No matter how your current driveway is made, if you want to extend it without breaking the bank, permeable pavers from TRUEGRID are the way to go. Their installation is so easy even your kids can help you, and the total cost can be outrageously low especially if you use TRUEGRID ROOT for stabilized grass parking. Whether you use grass or gravel with TRUEGRID, you’ll never have to spend money on maintenance, even years down the road.

In addition, their flood-prevention capability, eco-friendliness, stylistic variability, and long-term durability mean that using TRUEGRID permeable pavers is the best way to widen or lengthen your driveway without breaking the bank.

option for the base layer of a gravel driveway is item #4. Item #4 is comprised of sand, dirt, and golf ball-sized stones. This type of gravel is available in a few different variations including recycled item # 4, which is made up of recycled stones, brick, blacktop, concrete, and rock.

There is also quarry item # 4, or crushed limestone, gray item # 4 which appears dark grey in color, and crushed bluestone item #4. Crushed bluestone item #4 is usually found in municipal driveways, though.

The middle layer of a gravel driveway features stones closer to golf ball size, with #57 stone being the prominent type of gravel. Otherwise known simply as crushed gravel, #57 stone also helps promote drainage.

5 Types of The Best Surface Gravel for Driveaway

There isn’t a lot of variety for the bottom layers of a gravel driveway, however, there are more options when it comes to finding the best gravel for driveway surfaces. Among the other options are crushed stone #411, quarry process, pea gravel, jersey shore gravel, marble chips, and river rock. These are the best options for driveway surfaces gravel, because they are small stones combined with rock dust, which makes a more solid driving surface.

1. Crushed Stone #411

It is crushed up #57 stone combined with rock dust. This mixture is able to handle moderate traffic from heavy vehicles.

2. Quarry Process

It is also called “crusher run” and works well for the surface of both driveways and walkways. It’s made from stone dust fines and crushed stone.

The stone dust will settle and become compact to create a semisolid surface that is smooth. It is important that you know that this type of surface gravel needs to be sloped towards the sides of your driveway for better drainage.

3. Pea Gravel

Pea gravel is popular gravel for driveway aesthetics. It’s made up of round, small stones that can come in many different colors. This type of gravel will easily migrate and spread under the weight of vehicles, though, and needs to be stabilized for long-term, maintenance-free usage.

4. Jersey Shore Gravel

It is made of yellow, tan, white, gold, and brownstones and looks quite a bit like sand. It’s similar to pea gravel since it needs borders or stabilizing pavers to prevent it from spreading.

5. Marble Chips

Marble chips are white and they sparkle in the sunlight. They typically cost more than other gravel types but are another favorite when it comes to being the best gravel for driveway aesthetic appeal. This type of gravel also needs a border or stabilization to prevent it from spreading, migrating, and washing away.

6. Blackstar or Blacktrap Rock

A very attractive dark gray gravel, this is an excellent choice as it is angular and locks together. When combined with stabilizing grid paving system, this provides a super durable and beautiful driveway.

A Better Alternative to Typical Gravel Driveways

Some of the aforementioned gravel types require stabilization, but the best way to construct any gravel driveway is by using TRUEGRID permeable pavers to lock in your gravel.

TRUEGRID PRO LITE and PRO PLUS stabilizing pavers simply require fill gravel and surface gravel, although you can use the same type of gravel for both. The fill gravel is poured over the top of a piece of fabric at the bottom of the excavated area where you want your driveway that provides drainage for water and other liquids.

It is then compacted and leveled before TRUEGRID permeable pavers are snapped in place over the surface. Next, your surface gravel of choice is poured over the pavers and locked into place using a heavy roller or vehicle. This weighs the pavers down and locks them securely into place.

The main benefit of using TRUEGRID pavers to build a gravel driveway is that they will keep your gravel in place, eliminating the need for almost any maintenance during the course of your driveway’s lifetime.

A properly installed and maintained TRUEGRID gravel driveway is durable enough to handle all types of vehicle traffic and will last up to 60 years without cracking or breaking down in the sun, rain, or other types of weather like asphalt does.. Choosing the best gravel for driveway usage is only part of the equation.

If you want to build your gravel driveway the maintenance-free way, get in touch with the pavement professionals at TRUEGRID today for a quote.

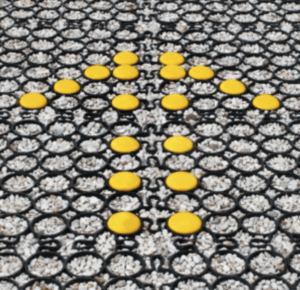

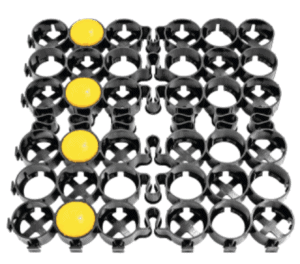

How do you best utilize a gravel lot? Without stripes, parking will be inefficient and unorganized. Paint on gravel just does not work, unless you enjoy painting frequently. Of all the benefits of using permeable pavers to build a gravel parking lot, one of the most overlooked is that using parking lot markers to organize and stripe your lot ensures maximum efficiency and utilization.

If you’re curious about the benefits of permeable-paver gravel lots and the fact that their parking lot markers offer far more value than the painted lot lines commonly found on asphalt and concrete lots, let’s look at three of the biggest ones.

1. Cost-Effectiveness

Cost-effectiveness is probably the most valuable benefit of using gravel parking lot markers instead of painted lines. You might think that neither could cost very much, but that’s not necessarily true.

While gravel parking lot markers are a low-cost, one-time expense, the same cannot be said for painted lot lines. These lines require frequent refreshing and repainting. The one time cost is about the same, but paint needs to be repeated. The plastic markers do not and will last the 30 plus year life of the lot.

These spot markers snap into place with no tools needed. They can be repositioned easily if needed.

2. Stylistic Versatility

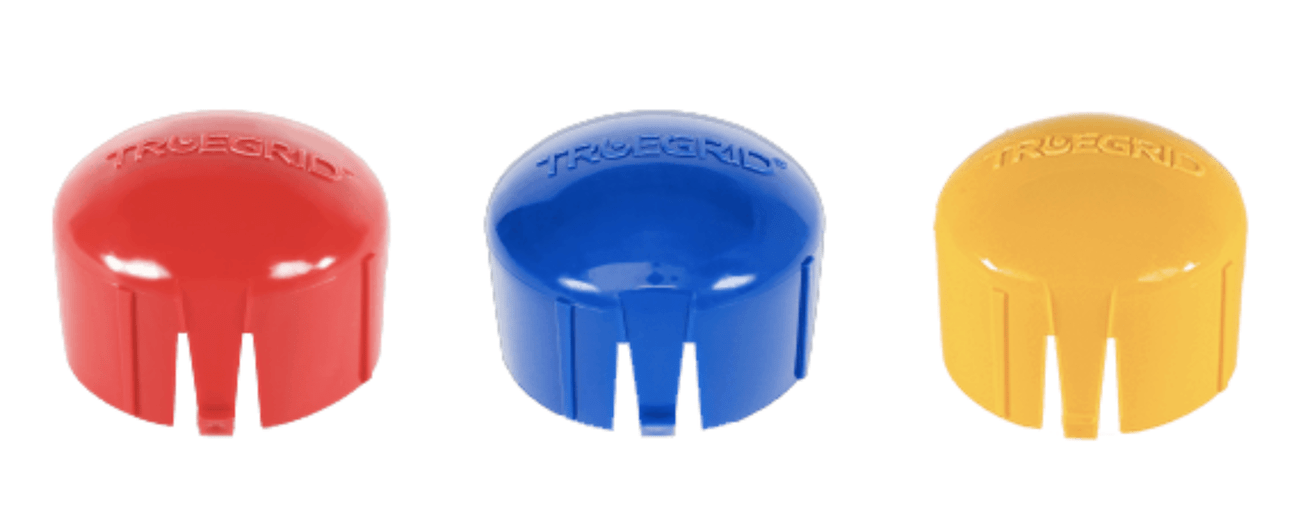

Painted lot lines typically come in one of two colors; white or yellow, which we are all accustomed to seeing as this is the current standard.

So, when you go with an asphalt or concrete parking lot, you are limiting yourself stylistically and preventing your business from standing out in some small way.

It might not seem important to some business owners, but in today’s climate, where every edge and unique characteristic helps a business stand out among the rest, installing a boring asphalt or concrete parking lot can be a subtle failure when it comes to getting noticed.

Gravel parking lot markers, on the other hand, come in different colors, like white, red, yellow, and blue. Besides adding color to your parking lot, you can designate certain spots for certain uses and create markings, like arrows, and reposition them with ease.

Thanks to the simple, snap-in installation of these markers, you can move them around instantly depending on who’s going to be parking in your lot, what events you’re having, and any other shifting variables.

3. Safe for all climates

Another huge benefit of using gravel parking lot markers over painted lot lines is their eco-friendliness. The grid is made from 100% recycled HDPE. The markers are made with a long term UV inhibitor to last for decades.

The standard domed SuperSpot markers are great for high visibility. Add safety by using reflector SuperSpot parking markers at the end of lines or for entire stripes.

In cold climates use SnowSpots which are flush to the surface and are easily snow ploughed.

Compared to painted lot lines, which are made of hazardous chemicals and need to be constantly replenished, gravel parking lot markers are far more sustainable and may contribute a positive PR boost for your business.

4. Visibility

Unlike paint, TRUEGRID’s gravel parking lot markers are made from highly reflective material, which makes them much more visible than regular lot lines and also means that their visibility never fades over time.

There’s nothing more unprofessional than having your customers and guests not know where to park because they can barely see your lot lines, so gravel parking lot markers can go a long way toward improving your image in that regard. Visibility is also at a premium in areas where rain, snow, and other weather conditions conspire to make your lot lines harder to see.

Painted Lot Lines are a Thing of the Past

Gravel parking lot markers are ushering in a new era of parking for businesses everywhere. If you are tired of paying a crew to repaint your lot lines, or you want to maintain a professional-looking parking lot over many years without having to invest in its maintenance, a permeable paver gravel parking lot may be in order.

The cost-effectiveness, stylistic versatility, and eco-friendliness of these parking lots and their lot line markers are just too beneficial to pass up in today’s business environment. For more information on gravel parking lot markers and a better paving solution, contact Truegrid today.