Asphalt Damage and Distress: 13 Types of Pavement Deterioration

Asphalt is one of the most common types of paving material available today. The majority of parking lots are built with asphalt, which is found in many other paving applications as well. What many people don’t realize, however, is that using asphalt has many downsides. The biggest one is probably the sheer variety of damage it can create over its lifetime.

Types of Pavement Deterioration

In case you were unaware of the vulnerability and fragility of asphalt, here are the main types of damage it tends to make and the variety of ways it tends to deteriorate over time.

1. Potholes

Potholes, one of the most well-known types of asphalt damage, occur when the area beneath the surface of the asphalt has been compromised, not repaired, and completely failed. This eventually leads to a depression in the pavement, known as a pothole. Potholes are dangerous and can lead to injuries as well as vehicle damage.

2. Fatigue Cracks

Another common type of asphalt damage, which can occur even more frequently than potholes, is fatigue cracking. These cracks often appear in a pattern similar to shattered glass or a spiderweb. They can occur either from water damage or an improperly installed subsurface.

Traffic and repeated heavy loads on the surface are then improperly distributed, resulting in cracking due to an improper weight distribution across the surface of the asphalt.

3. Blowouts

Essentially, a blowout is a massive pothole. Whereas potholes are relatively small in size, a blowout is like a shallow sinkhole, often expanding multiple feet across and lengthwise. Their cause is the same as for potholes, a failed base beneath the surface of the paved area.

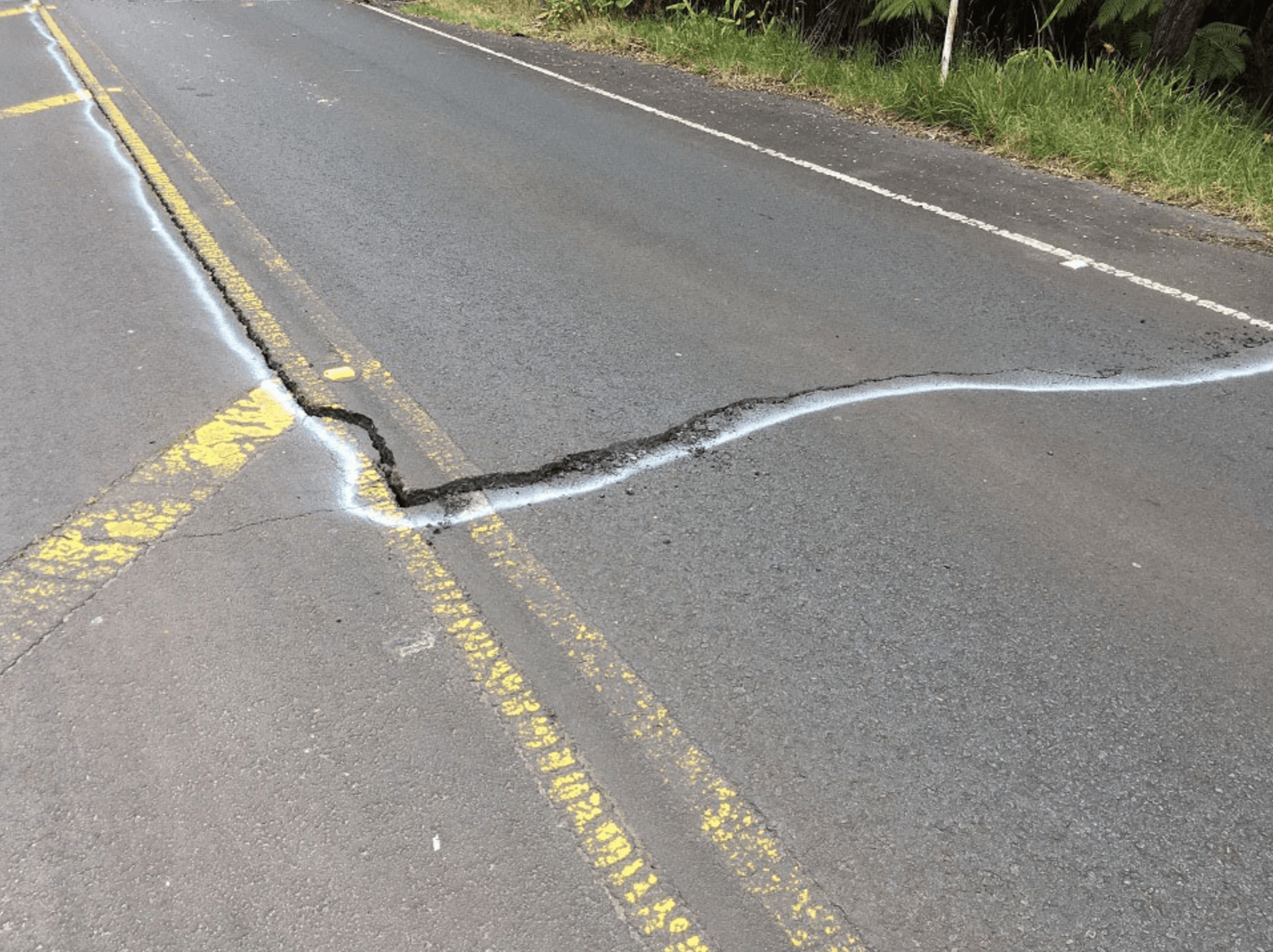

4. Reflection Cracks

Over time, when older cracks are simply covered up with more asphalt, reflection cracks develop. These are mirror images of the underlying cracks, hence their name.

5. Sinkhole

A sinkhole is one of the worst types of pavement deterioration. Sinkholes are the result of a complete erosion of the subsurface, usually from improper drainage or sewer or plumbing leaks. These create a hole in the pavement and can cause massive vehicle damage and injury if not addressed immediately.

6. Block Cracks

Block cracks appear as randomly arranged linear cracks, often several feet apart. They develop when an asphalt lot does not get much traffic, and the surface shrinks horizontally as the asphalt ages. They will result in water penetration and other asphalt problems if not filled.

7. Rutting

Rutting or ruts are caused by vehicle traffic. They appear as depressions in the shape and direction of commonly driven areas, usually the same size and shape as vehicle tracks. They develop if the asphalt does not have the capacity to bear the loads that are being carried on it.

8. Raveling

Raveling is asphalt damage that occurs when the gravel in the asphalt loosens and spreads. This will happen over time if the surface of the asphalt has oxidized. Raveling weakens the surface of the asphalt and will lead to greater issues if not treated.

9. Shoving

Shoving appears on the surface of asphalt as bumps or raised areas. It’s usually found where heavy vehicle loads regularly start and stop, causing inordinate asphalt distress in these areas.

10. Upheaval

Upheaval appears as a raised, often broken-open area of asphalt and is caused by an underlying swelling of the subsurface, which can be caused by frost or expanding soils.

11. Peeling

Peeling occurs when the surface layer of the asphalt dries out over many years and begins to peel away, revealing the sub-layer of asphalt that had been previously laid.

12. Root Cracks

Root cracks are caused by tree roots growing underneath a paved asphalt surface. They appear as winding, raised linear bumps and can eventually open up to become larger cracks.

13. Linear Cracks

Linear cracks are long cracks that develop primarily when water is able to penetrate the surface of the asphalt pavement. They are very likely to develop into open holes and require immediate attention.

A Low-Maintenance Alternative to Asphalt

If you want to avoid having to figure out how to fix a depression in an asphalt driveway ordeal with edge cracking or cracked pavement, you need a better alternative to asphalt —TRUEGRID permeable pavement is pavement made from 100% recycled plastic.

It’s much more durable than asphalt and requires almost no maintenance throughout its 60 year lifetime. A permeable pavement driveway or parking lot from TRUEGRID can last for decades and is competitive in price to purchase and install than commercial asphalt. It’s also eco-friendly and provides a built-in drainage solution, with a greater surface area, eliminating the need for an additional drainage system.

For a paving solution that’s cost-effective, durable, fast to install, eco-friendly, and stylish as well, TRUEGRID permeable plastic pavement is likely to be your best choice.

Contact TRUEGRID today for information on your project needs and custom samples.

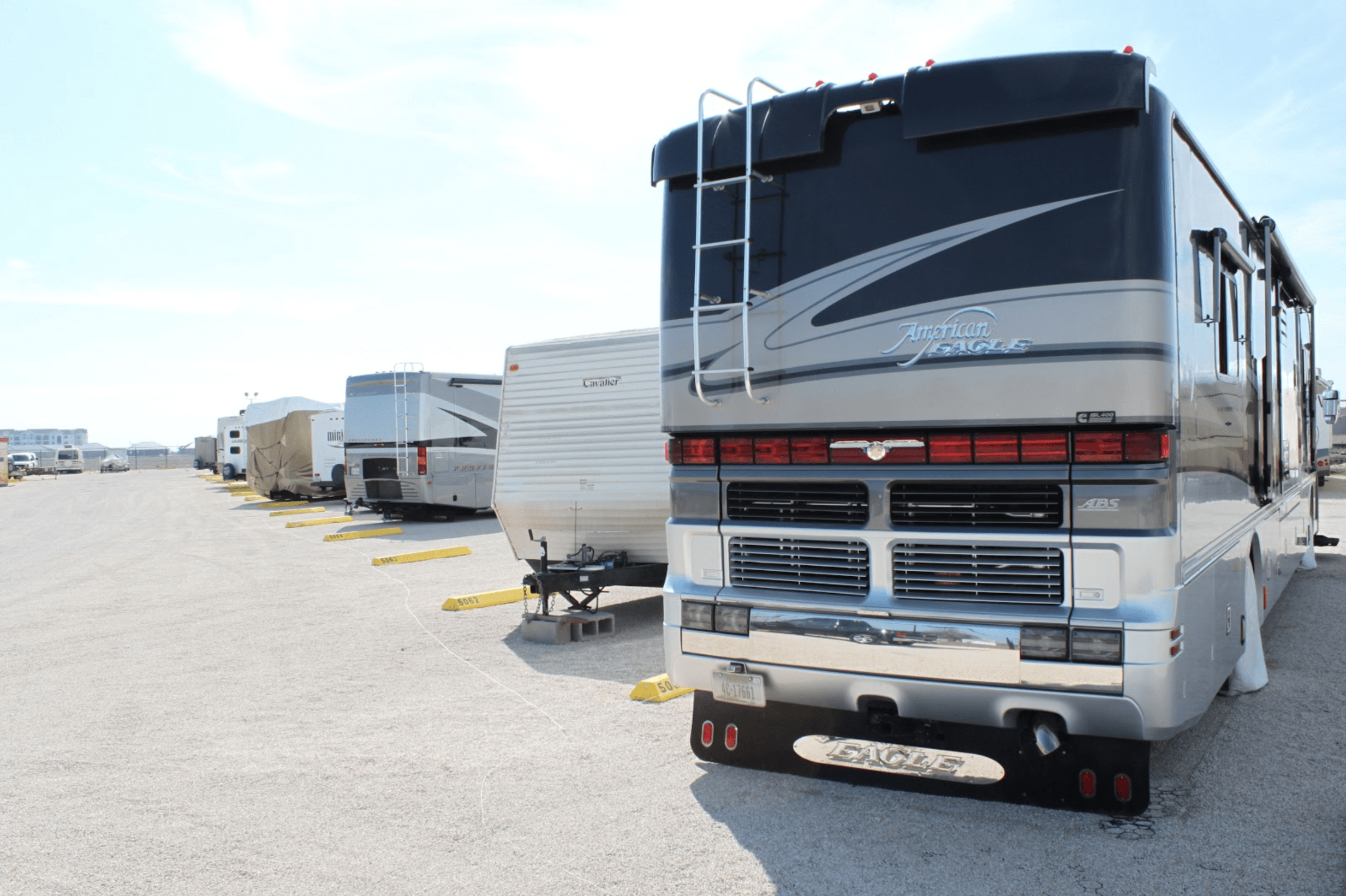

If you’ve ever owned an RV, you know that having a dedicated parking space is preferable to parking it on the street or in your driveway. RVs are generally too big to fit in a garage and heavy enough to leave indentations and tracks in your yard.

Of course, you might be the owner of a self-storage company looking to add some specialized parking for RV owners or even the owner of an RV park looking for the best material with which to build an RV parking lot and roadways in your park. In any such scenario, there’s one type of pavement material that stands head and shoulders above the rest when it comes to RV parking.

In case you need parking space for one or more RVs, let’s look at TRUEGRID permeable pavers and why they are the superior option.

Lightning-Fast Installation Time

Because the materials needed to build RV parking with TRUEGRID pavers are pre-made, the installation process is incredibly simple. If you are dealing with an undeveloped plot of land that may or may not need stormwater detention, simply excavate to the needed depth, fill with clean angular gravel for detention, and compact. If your lot or roadways are gravel and simply need stabilization to eliminate maintenance, the TRUEGRID option is absolutely the least expensive and easiest option. Simply level and compact gravel, lay the grid on top, and fill with gravel for maintenance free pavement that will last 60 years at a low investment cost. If drainage and detention is needed, lay the interlocking pavers on top of the gravel and fill them with more gravel, running a compactor over the surface to press the gravel into the pavers. This gives you 100% land use while providing a naturally attractive aesthetic and a strong, cool surface.

Installation time is fast and the permeable pavement meets previous cover and stormwater codes. No added detention areas are required in most cases and 100% land use is possible.

If you’re an RV-park owner looking to stabilize an existing, unstabilized gravel lot, the process is equally as simple. Simply scrape back the existing gravel, roll to level the subgrade, lay a fabric as a barrier between the lot and the subgrade, lay down the TRUEGRID plastic pavers, fill them with gravel, and compact the gravel into the pavers. This is the fastest, most inexpensive way to stabilize a gravel lot and increase its longevity while nearly eliminating its maintenance requirements.

For residential owners, the installation process is so simple it can even be done as a DIY project, completed in less than a day as with most TRUEGRID installations. If you’re building a gravel parking space for your RV, the process is identical to both of the above-mentioned processes, depending on whether or not you want stormwater detention.

However, you can also use TRUEGRID ROOT pavers to stabilize a grass parking space for your RV. You simply lay them down and compact them into the grass. The grass will come up through the pavers, which will be nearly invisible to the naked eye, depending on the length of the grass. This is great for creating a hidden parking space.

Cost-Effectiveness

The cost of installing TRUEGRID pavers is less than that of concrete and competitive with asphalt. With TRUEGRID pavers, a commercial lot will generally cost around $5–$7 per square foot turnkey. Not only is the material cost lower than for most paving materials, but you’ll also save money on installation and long-term maintenance. 100% land use, no maintenance.

Eco-Friendliness

If the first two reasons weren’t enough to convince you, TRUEGRID pavers are also much better for the environment than asphalt or concrete. They are made from 100% post-consumer recycled plastic, so they have a net-positive impact on the environment.

They are also 100% permeable, meaning they absorb water for infiltration into the soil at over 1000 inches per hour with no runoff. No flooding, no ponding or pooling and no maintenance. Functionally and aesthetically in perfect harmony with Mother Nature, allowing stormwater to pass directly through and be filtered down to the water table, as it should.

TRUEGRID Pavers are the Perfect Parking Solution

When it comes to parking RVs, you need a heavy-duty solution that won’t break down over time or require maintenance. TRUEGRID plastic pavers not only possess this durability but are also cost-effective, quick to install, and great for the environment. In addition, they offer stylistic variety in the form of multiple colored aggregates and hidden grass parking spaces.

When you take all these factors into account, it’s hard to see why anybody in need of RV parking would choose a paving material other than TRUEGRID permeable pavers. They’re cheap, super-durable, environmentally-friendly, stylish, and versatile enough to handle residential, commercial, or industrial RV parking needs.

Contact TRUEGRID today for more details on a superior RV parking solution.

If you need to build a commercial parking lot, it has to meet a set of standards to comply with local codes and function as you need it to. Depending on the size of your lot and how much/what kind of traffic you expect it to see on a daily basis, there are a number of ways you can ensure that it performs up to standard.

In case you’re about to build a commercial parking lot, let’s go over some factors to consider to make sure it abides by local codes and ordinances while also providing you with the highest possible level of functionality and value.

Drainage

All commercial parking lots need to be able to drain a certain amount of water per hour, which ensures they can handle the maximum level of rainfall, should it occur. Without proper drainage, the lot might contribute to flooding in adjacent properties or put an undue burden on the local water system.

For impermeable materials like concrete and asphalt, this generally means building the parking lot with at least a 2% slope toward a storm drain or other drainage outlet. One way to avoid having to slope your parking lot, however, is to build it with TRUEGRID permeable pavers.

These pavers are 100% permeable, so all stormwater will drain directly through them. They are also guaranteed to meet local codes wherever you are because they can drain water at up to 1,000 inches per hour. A permeable paver lot from TRUEGRID will also drain over the entire surface of the lot, rather than the designated inlet areas in asphalt or concrete lots.

Stormwater Detention

Not only does a commercial lot need adequate drainage, it also requires a stormwater detention area. For asphalt and concrete lots, this means designating part of the parking lot for this stormwater detention, which sacrifices square footage that could be used for more parking spaces.

With TRUEGRID permeable pavement, however, the stormwater detention pond is built into the parking lot. Storm water will drain into and be held in the base rock and filled gravel. So, the detention pond is located underneath the parking lot and doesn’t require sacrificing any of the square footage of the lot.

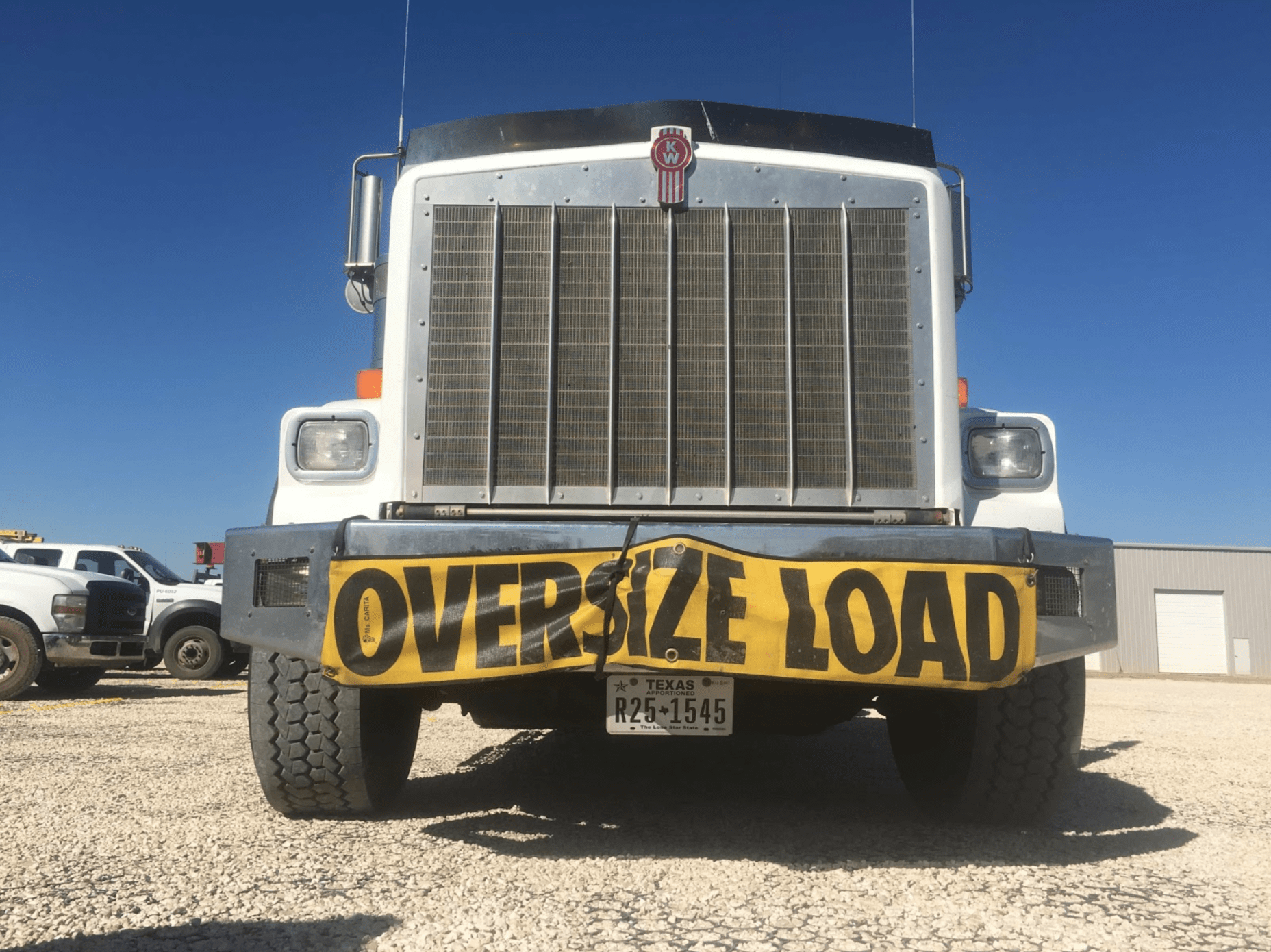

Strength

Depending on what kind of traffic you expect your commercial lot to see on a regular basis, your lot will need to meet certain strength requirements. Asphalt is too fragile to handle traffic that exceeds certain weight limits, especially on hot days.

Concrete and plastic permeable pavement, on the other hand, are viable options for handling much heavier loads. TRUEGRID permeable pavement has even been proven to handle loads of over 8,000 psi when filled with aggregate.

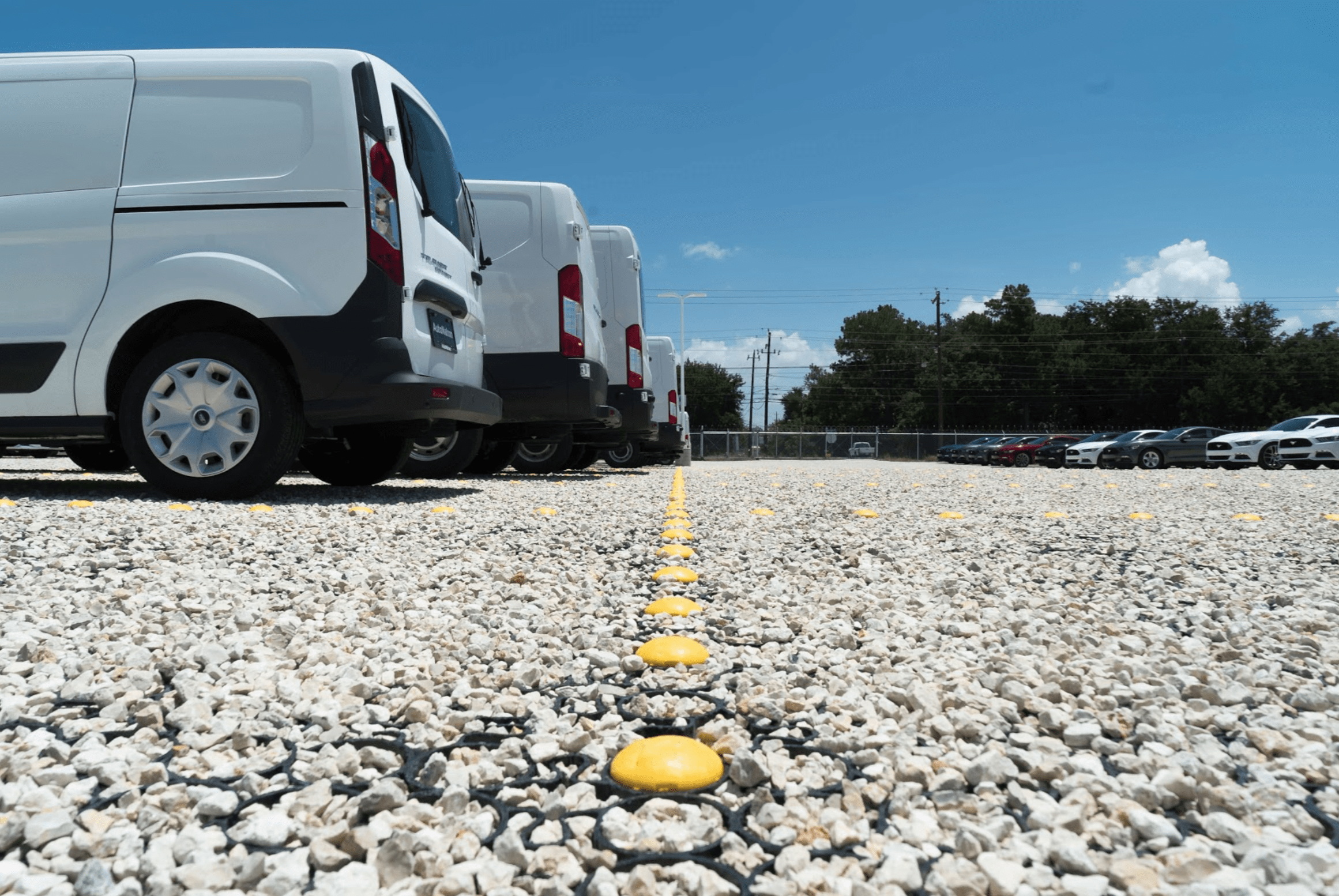

Striping

Striping allows for greater space utilization and parking capacity for your parking lot. Local ordinances may dictate that commercial lots include striping for safety reasons. With asphalt or concrete, this means painted lot lines that require regular re-painting to stay visible. With TRUEGRID SuperSpot markers, however, you can fully maximize your parking capacity and meet local safety standards without ever having to re-paint your lot lines.

SuperSpot markers snap into place in seconds and can even be moved and rearranged to create directional lines or patterns when necessary. For additional safety and visibility, SuperSpot reflectors can be added to the ends of lines as well.

Longevity and Low-Maintenance Requirements

Technically, all you have to do as a commercial lot owner is meet local standards. If you want to exceed local standards and achieve the highest level of cost-effectiveness and functionality, however, TRUEGRID permeable pavement is one way to do that.

TRUEGRID permeable pavement requires the least maintenance of any parking lot material, meaning you can essentially “set it and forget it.” They are also incredibly easy to install, costing less than almost any other material and taking far less time as well.

Exceed Standards and Slash Costs with TRUEGRID Permeable Pavement

It’s one thing to meet local standards and codes when it comes to laying a commercial lot, but if you want to exceed standards, maximize your land use and parking capacity, and cut your costs, TRUEGRID permeable pavement is the best way to do so.

The installation time and cost is incredibly low because building a TRUEGRID permeable paver lot is as simple as snapping together LEGO blocks. Unlike asphalt and concrete, it requires no cure time and can even be done in a DIY fashion.

Even for commercial lot contractors who are new to TRUEGRID products, getting up to speed is as simple as reading the TRUEGRID 3-step guide. Not only is installing a TRUEGRID lot faster and typically more cost-effective than asphalt or concrete, it’s also more durable and requires less maintenance while also being much more eco-friendly.

Taking all of these factors into account, it’s safe to say that there’s no better or more cost-effective way to not only meet but also exceed local standards than by building your commercial parking lot with TRUEGRID products.

Contact a team member at TRUEGRID for a custom quote for your commercial parking lot.

Clay brick pavers are commonly used in both commercial and residential paved areas. They are found in walkways, sidewalks, fire lanes, and other paved areas that expect regular traffic and need to bear weight.

Disadvantages of Clay Brick Pavers

While some people appreciate the look of clay brick pavers, they can pose a lot of problems that may make using them not worthwhile. Let’s take a look at some of the disadvantages of clay brick pavers and why maybe, they shouldn’t be your first choice when considering paving a commercial or residential area.

1. High Cost

The cost of clay brick pavers in any setting is relatively high compared to other materials. While plastic permeable pavers are the most cost-effective paving material, brick comes in on the expensive side, outpricing both asphalt and concrete. Only natural stone pavers, like limestone, marble, sandstone, granite, and bluestone, cost more than clay brick pavers. Price can be an issue, especially if you’re paving a large area.

The average cost of clay brick pavers is about $5 per square foot, but that’s without factoring in installation costs. Unless you’re installing them yourself, the cost of installing clay brick pavers will range from $10 to $20 per sq ft. Depending on the design and style of the clay brick pavers, however, it could cost you even more.

2. Durability Issues

Clay is a quite fragile material. Unlike concrete, there’s not much you can do to make it more durable, either. Clay brick pavers will easily weather over time from moisture and sun exposure. They can also be chipped or cracked quite easily and would need to be replaced if this happens.

In comparison to a highly durable material like recycled plastic pavers, clay brick pavers are easily damaged. There is also no quick fix for repairing them, unlike asphalt, which can be repaved, or concrete, which can be resurfaced.

3. Maintenance Requirements

Clay brick pavers require regular maintenance to prevent them from breaking down, flaking, peeling, and wearing away. Whether they are laid in sand or mortar, clay bricks need to be covered with a sealant. Without regular reapplication of this sealant, clay pavers will quickly break down.

They also need to be pressure washed at least twice a year, and sealant needs to be reapplied after each washing. New sand must be packed into the crevices between the pavers or new mortar applied after each washing, depending on how they are laid.

You also have to take care to remove any weeds or moss that might spring up between the clay brick pavers. Compared to a low-maintenance paving material like plastic permeable pavers, clay brick pavers require a moderate to high level of maintenance to keep them in tip-top shape.

4. Lack of Permeability

While clay brick pavement can be somewhat pervious if the joints are filled with sand or finely ground gravel, they don’t compare in performance to a material like plastic permeable pavement.

Heavy rain will create an overflow of water in most cases, leading to flooding if there isn’t a stormwater drainage system in place. While this isn’t an issue for small clay brick paver applications or residential usage that is near a local drainage system, it can cause major problems in commercial settings or residential areas prone to flooding.

5. Lack of Aesthetic Variety

While the look of clay brick pavers is one of its main selling points, they are somewhat limited when it comes to stylistic variety. The bricks only come in rectangular shapes in most cases, and colors are limited to reds and browns. This can be a major downside for those who want to be creative with their pavement design.

A Better Alternative to Clay Brick Pavers

Whether you’re looking to pave a commercial or residential area, there are better alternatives to clay brick pavers. Permeable plastic pavers, for instance, provide you with a clean, attractive surface that is far more durable and cost-effective.

These pavers are typically made from 100% recycled plastic, which is more eco-friendly and requires almost no maintenance compared to clay brick pavers.

They also offer a bit more stylistic variety because you can use multiple types and colors of aggregate to fill them, and the pavers themselves can be trimmed and cut to fit any shape you want. So, you can use them to build anything from a small walkway to a massive parking lot.

If you want a paving material that can handle heavy traffic, sun exposure, and rainfall without wearing down or requiring maintenance, permeable plastic pavement is definitely the way to go. The cost-effectiveness, eco-friendliness, durability, stylistic variety, and ease of installation that these pavers provide are unmatched by any other paving material on the market.

Contact TRUEGRID today for more information on a better-than-brick paving solution.