The Best Paving Solution for Heavy Equipment

If you’ve ever worked with heavy equipment, machinery, or vehicles, you know they take a toll on the pavement they drive on. Whether you’re driving bobcats, tractors, commercial vans and trucks, cement trucks, or any other type of heavy equipment, the amount of abuse they put on roads and parking lots is substantial.

Especially for asphalt and concrete pavement, this type of equipment can lead to pavement breaking down exceptionally fast and requiring many expensive repairs as a result. This can eat away at your bottom line over time, but what if there was a better solution? Thankfully, there is.

Innovations in pavement technology have been made that allow it to handle all the abuse in the world without breaking down nearly as fast as your typical concrete or asphalt pavement. So, in case you’re someone who deals with heavy equipment and/or vehicles on a regular basis, let’s take a look at a superior pavement solution for them.

The Downsides of Driving Heavy Equipment On Concrete and Asphalt

One of the reasons why it’s so inefficient to use asphalt and concrete for pavement that is going to be used by big, heavy equipment is the lack of durability found within both materials.

Both concrete and asphalt are impermeable, meaning liquid cannot pass through them. This is a problem when it comes to durability because water will eventually infiltrate a compromised surface layer of concrete or asphalt and seep into the subsurface layers.

Once there, it causes erosion and widens the cracks it got in through when it goes through freeze/thaw cycles. It can also eventually seep beneath the pavement itself and wash out the soil below, leading to total collapse of the pavement.

Also, both concrete and asphalt are easily damaged by heavy traffic and friction. This leads to the need for constant resealing and resurfacing of both materials and is very costly for whoever has to foot the bill.

TRUEGRID Permeable Pavement is the Number One Solution for Heavy Equipment

Heavy equipment requires heavy-duty pavement. That’s where TRUEGRID permeable plastic pavers come in. These pavers are far more durable than concrete or asphalt, for starters. They can handle the weight of a monster truck driving off a ramp and landing on them while empty and they still won’t break. So, it’s safe to say this heavy equipment paving can handle even the heaviest equipment or vehicles you have.

Not only that, but TRUEGRID PRO PLUS and TRUEGRID MACK pavers will last up to 60 years before needing to be replaced. They’re UV-resistant and 100% permeable, draining at over 1000inches per hour, which eliminates the need for additional drainage systems. They require almost no maintenance in comparison to asphalt and concrete which need to be regularly attended to.

These pavers provide superior grip for large vehicles and equipment, allowing the often oversized wheels to effectively change direction without displacing any of the gravel within the paver cells. The installation process for heavy equipment paving with TRUEGRID pavers is also much faster than what you commonly find with concrete and asphalt.

All it requires is a simple excavation, a protective fabric laid at the bottom of the excavation, a gravel base below the snap-locked grid pavers, and another layer of gravel fill into the top of the interlocking pavers which is then compacted with a vehicle or heavy roller.

Once the empty cells on the surface are filled with gravel, the patented pavers are weighed down and prevented from moving or shifting even under the extreme weight of heavy equipment. No more ruts, potholes, ponding or mud.No more gravel refill or maintenance.

TRUEGRID Pavers are Eco-Friendly Too

While you might expect heavy equipment paving to have somewhat of a negative environmental impact, this isn’t the case with TRUEGRID products. Their pavers are made from 100% post-consumer recycled plastic which is a far cry from the massive carbon footprint of both concrete and asphalt.

Not only that, but these pavers can be outfitted with a variety of accessories like SUPERSPOT markers, REFLECTORS, and PLATE markers for fire lanes and other special designations on your pavement.

These reduce the need for maintenance even more because they’re permanent and never have to be repainted unlike lot lines and other painted-on markings. The reflectors are also great for helping visibility when parking huge pieces of equipment.

Make Sure Your Pavement Can Handle Heavy Equipment with Ease

If you’re looking for durable and effective heavy equipment paving, look no further than TRUEGRID pavers. With an unmatched combination of durability, permeability, grip, quick installation, eco-friendliness, accessories, and low maintenance requirements, it’s safe to say they outperform your standard asphalt and concrete pavement by a country mile.

If you work with heavy equipment and/or vehicles, don’t hesitate to take the leap and get in touch with TRUEGRID today for a quote on the most superior heavy equipment paving option on Earth.

A church is typically a place where quite a few people congregate together at once. Thus, parking is especially important when it comes to the construction of your church.

Services tend to be smaller on weekdays, but Sundays especially can see dozens and dozens of vehicles looking for a place to park. Not only that, but many churches also offer a variety of services that require transportation of large groups of people at one time.

Whether it be sports events, public transportation for those without a vehicle, or another type of mass transportation, the use of bigger, heavier vehicles like vans and busses can take a toll on the average parking lot.

In case you’re in charge of church parking lot construction, let’s take a look at the easiest way for you to build a parking lot that lasts a long time without needing much maintenance.

Alternatives to Asphalt and Concrete Are Needed for Church Parking

Most church parking lots you know of are probably built with either asphalt or concrete. These materials are durable and relatively cost-effective, but they also come with a variety of problems that churches shouldn’t have to deal with. Additional drainage systems are often required for these lots so they don’t flood when it rains. Installation of asphalt and concrete can take weeks to complete as well.

They also tend to break down rather quickly and need to be repaired often, especially when dealing with traffic from heavy vehicles like vans or busses. Both asphalt and concrete need to be resealed every few years and resurfaced at least once per decade. There are also painted lot lines which fade and need to be repainted.

All of these maintenance efforts are costly and can put a burden on churches that are already scarcely funded. There is, however, a much better alternative for building a church parking lot.

TRUEGRID Permeable Pavement is the Go-To Material for Church Parking

For the highest quality, easiest material to build a church parking lot with, the solution is without a doubt, TRUEGRID plastic permeable pavers.

The installation of TRUEGRID PRO and TRUEGRID PRO PLUS pavers is easier than installing almost any other type of pavement that is available.

It starts with a simple excavation of about 12 inches, after which a piece of fabric is laid at the bottom of the pit to prevent gravel from migrating into the soil.

Next, gravel of your choice is poured into the pit and compacted, filling it to the top. The interlocking pavers are snapped into place as easy as LEGO bricks over the top of the pit, and more gravel is poured over the top of them and driven over or compacted into them with a heavy roller. This weighs the pavers down and prevents them from shifting around as vehicles drive on them.

The entire process will typically take less than a day to complete for most church parking lots, and it doesn’t require the use of any complicated machinery. For churches that need a parking lot fast, this is the ideal pavement solution.

Another plus is the 100%-permeability of TRUEGRID pavers. They allow extremely heavy rainfall to drain directly through them and into the soil below. This prevents the need for costly drainage systems and allows the paved area to work in better harmony with nature, lessening the burden on local sewer systems.

For the durability needed to handle regular vehicles and heavy vehicles like busses and vans, TRUEGRID pavers are the solution. These pavers are so durable that even when empty, 80,000 lb gravel trucks can drive on them during construction with no problem to speed construction and reduce costs.

They’re also UV-resistant and unaffected by extreme temperature fluctuations. This resilience will keep them usable for over 60 years with no or minimal maintenance required. TRUEGRID also makes SUPERSPOT markers for lot lines that never need to be repainted.

Another important aspect of TRUEGRID pavers is the fact that they are some of the most eco-friendly paving materials available anywhere. Made from 100%-recycled plastic, they have a net-positive impact on our environment, rather than a net-negative impact like asphalt and concrete.

Give Your Church the Parking Lot it Deserves with TRUEGRID

Whether you need a whole new parking lot installed or you’re just looking to build some overflow parking, TRUEGRID permeable pavers are the perfect choice.Now your flock can attend services without stepping through puddles during rain storms as this system drains instantly at over 1000 inches per hour. They are cost effective, durable, require very little maintenance, eco-friendly, permeable and are available in a variety of styles.

If you’re in need of a new church parking solution, contact TRUEGRID today to get in touch with a pavement specialist for a quote.

For many homeowners, gravel driveways are a favorite choice for parking their vehicles. Not only is gravel relatively inexpensive compared to other types of driveway materials, it’s also available in many different styles and can be very durable when combined with the right type of underlayment.

There are many types of gravel driveway underlayment you can use to help stabilize your gravel, and underlayment is a far better option than simply using loose gravel. There are so many different choices available when it comes to gravel underlayment, however, that it can be hard to settle on a final selection.

Thankfully, we’ve got you covered. In case you’re looking to build a gravel driveway and are undecided on how to stabilize it, here are some of the benefits and drawbacks of a few different types of popular driveway underlayments:

The Benefits of a Driveway Underlayment

A driveway underlayment fabric between your driveway gravel and the earth beneath it helps to prevent the growth of weeds from below and the spread of gravel, first and foremost. Gravel spread is the number one problem with loose gravel driveways and the right underlayment can help mitigate or prevent it from happening entirely, which is also why builders use gravel road underlayment as well.

Underlayment can also help to prevent ruts and divots from developing in your driveway, because they make it harder or in some cases, impossible for vehicle traffic to cause bare spots which then erode away into ruts and divots under repeated traffic.

The Best Drive Underlayment Choices

Weed barrier fabric is an affordable option that can works to stop unwanted growth but doesnt help much for grave spread or loose gravel. It does provide a barrier between the gravel and underlying soli to reduce mud from working its way up. It works with primarily small gravel. Although it’s not the best underlayment for a rock driveway with larger, sharp stones because it can tear easily, it can work in limited capacity with small, rounded gravel to prevent weeds from growing up through your driveway. It’s also semi-permeable and will allow water to seep through, though flooding is still possible with heavy rainfall.

Geotextile fabric is a favorite among homeowners looking for the best underlayment for gravel driveway because unlike weed barrier fabric, it’s specifically designed to stabilize gravel and bear heavy loads. Though not as durable as pavers,nor does it stop gravel from spreading, geotextile fabric can even be used on its own to stabilize earth and loose soil. It can also be used in conjunction with gravel and is typically more permeable than weed barrier fabric.

TRUEGRID Works Best for Stabilizing Gravel Driveways

One option that most homeowners find superior to even the best gravel driveway underlayment fabric is TRUEGRID pavers. TRUEGRID PRO and TRUEGRID PRO PLUS pavers are perfect for stabilizing gravel and providing a durable, level surface that will never develop ruts, divots, or bare spots. Though a piece of fabric is laid at the bottom of your excavated driveway before the gravel is poured in, the lion’s share of the functionality comes from the permeable plastic pavers themselves.

The fabric at the bottom keeps the gravel from migrating into the soil below and acts as a weed block as well. The interlocking grid pavers snapped over the full gravel pit keep the gravel locked firmly in place. Gravel is also poured and spread into the empty cells on the surface of the pavers. This provides the best possible way to eliminate gravel maintenance and stops the loss or spread of gravel.The TRUEGRID system is 100 % permeable , so no more puddles or ponding in your driveway, and is strong enough for any type of cars or trucks and will outlast asphalt and concrete. .

Made from 100%-recycled plastic, TRUEGRID pavers are eco-friendly and permeable enough to handle a heavy downpour of rain without flooding. They utilize hard, angular gravel as a drainage method and are compatible with many different types and colors of gravel, allowing for maximum stylistic versatility.

Durable enough to handle the full weight of a monster truck jumping off a ramp and landing on them, or 18 wheeler traffic, TRUEGRID plastic pavers will last you more than 60 years They also require no or minimal maintenance throughout their lifetime.

The permeable pavers produced by TRUEGRID are immune to damage from both cold and hot temperature fluctuations, can be used in any climate or soil and are UV protected as well.They do not stain like concrete or asphalt for auto fluids or leaks..

These pavers work especially well for driveways with any amount of slope to them, unlike most driveway underlayment fabric alone which cannot fully prevent the spread of gravel when working against gravity. The installation process is also just as quick as it is with most underlayment fabrics, taking less than a day to complete in most cases.

Stabilize your Gravel Driveway with a Professional-Grade Product

TRUEGRID pavers can be used to build parking lots, walkways, fire lanes, and driveways. Why bother using a cheap underlayment like a weed barrier fabric or even a geotextile underlayment when you could implement permeable plastic pavers?

TRUEGRID pavers provide higher quality durability and permeability while also having lower maintenance needs and more stylistic variety as well. If you want to stabilize your gravel like the pros do, don’t hesitate to get in touch with a pavement specialist at TRUEGRID today.

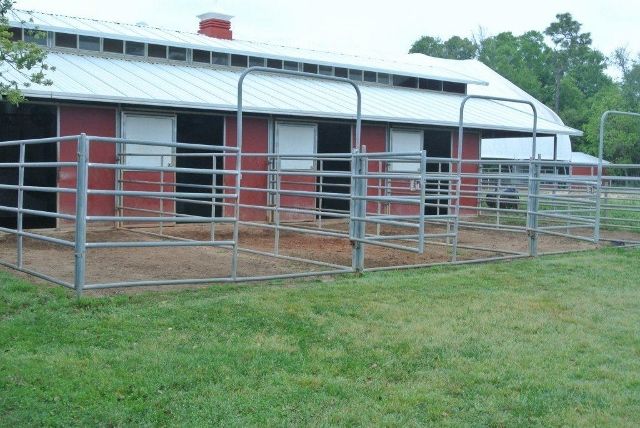

When it comes to building a horse barn, special considerations need to be accounted for if you want the best care for your horses. One of the biggest things to consider is what kind of flooring you’re going to use for your horse barn. Horses have hooves on their feet and without the right kind of flooring to support their immense weight, their hooves can become sore, swollen, and even infected.

Unfortunately, many people still use rubber pavers for horse barns but they are far from ideal. Although they are inexpensive and durable, rubber pavers can be harmful for your horses’ feet and can have a negative impact on their quality of life at the very least. There are, however, much better alternatives to interlocking rubber pavers for horse barns, such as TRUEGRID permeable plastic pavers.

In case you’re interested in building your horse barn with a superior material, as opposed to traditional equine rubber pavers, let’s take a look at the many benefits to be gained from using permeable plastic pavers in your barn flooring.

Rubber Pavers Are a Bad Choice for Horse Barns

When it comes to the optimal choice of horse barn pavers, TRUEGRID is the best option. One of the biggest downsides of rubber barn pavers is that they are notoriously hard to clean. Horse barns can be dirty places, with dirt, grit, straw, and other debris.

If you want to keep your horse barn clean, you’d like to be able to take a quick broom to the floors and be done with it, but the debris tends to stick to rubber pavers and make it hard to sweep. For proper cleaning you’d need a pressure washer, which can be a costly addition.

Thick rubber barn aisle pavers also need to be set in sand, which makes them a poor choice for barn aisles. The thicker equine pavers are not good for use in a wash stall because the water will run between them and into the sand below, causing it to become caught up between your pavers.

Non-slip surfaces are the main selling point of rubber pavers, but reground rubber has less of a non-slip quality than stranded rubber. It also crumbles easily along the edges when pushed against a hard surface like the side of a stall. Standing urine and standing water will also reduce the longevity of rubber pavers.

Another negative characteristic of using rubber pavers in your horse barn is that while they are often available in up to 4 colors, the color will fade out by about 25% almost immediately. This is due to the certain binding agents which are used in the production of pavers and which aren’t suited for friction and traffic.

Interlocking rubber pavers with supposed permeability tend to float once water seeps below them. You need a combination of thin rubber pavers atop an already paved surface such as concrete in order to prevent floating.

TRUEGRID Permeable Plastic Pavers Are Perfect for Horse Barns

TRUEGRID PRO PLUS pavers are perfect for use in horse barns for a variety of reasons. They keep surfaces mud-free for better health of the horses and livestock. They are more permeable than many interlocking rubber pavers and the liquid that drains through them doesn’t cause them to float. Instead, it drains directly down into the underlying rock or soil and eventually back into the water table, cleansing all the txins beforehand and keeping the animals away from their own waste. They drain instantly at a 100%-permeability rate and there is no need for resetting.

TRUEGRID pavers are also more durable than many types of rubber pavers. Made from 100%- post-consumer recycled plastic, they will never crumble, snap, or break. You can expect over half a century of use out of them before they may need to be replaced. They’re also much easier to clean and maintain, as debris doesn’t stick to them as easily as it does to rubber.

TRUEGRID gravel-filled pavers also have a non-slip quality to them and provide excellent traction for horses and people alike. They do not hold standing urine or water and as such, cannot be compromised by these fluids. Another benefit of TRUEGRID pavers is that the color won’t fade like it does with rubber.

You can also choose from a variety of different colored gravel, whatever is available and least expensive in your area. The eco-friendliness of TRUEGRID pavers is an added benefit, since they are one of the most environmentally-conscious paving materials on the market and they have a very low carbon footprint.

Give Your Horses Better Flooring with TRUEGRID Permeable Plastic Pavers

The installation process can be DIY completed in one day. Great for barns, paddocks, feed areas and runs, TRUEGRID pavers have unmatched durability, are easy to install and have 100% permeability, TRUEGRID low-maintenance plastic pavers are the perfect choice for horse barns, both large and small. If you want to build the best barn for your horses, order online or get in touch with a pavement specialist at TRUEGRID today for a quote.