3 Ideas for a Modern Permeable Driveway

Permeability is defined as the ability of a surface to allow liquid to pass through it. This quality is especially desirable in driveways and paved areas where water might otherwise runoff to the sides or pool in low places.

Permeable driveways are one of the most popular trends in home design right now, especially as eco-friendliness takes new precedent among homebuyers. Most driveways are made from asphalt or concrete and are almost universally impermeable as a result, however, many materials can be used to create a permeable driveway.

In case you’d like a driveway with a built-in drainage system, let’s look at a few modern ideas for how you can accomplish this:

1. Paving Stones

If you like the look of concrete pavers, natural stone pavers, or some other type of impermeable pavers, using a paving stone driveway is a great way to implement permeability.

A modern permeable driveway made from paving stones laid over a bed of gravel is an excellent way to help with water drainage. The cracks between your paving stones can be filled with sand or pebbles and this is where the water will drain into and through the subsurface bed of gravel.

Although certain paving stones can be expensive like natural stone pavers, others like concrete can be a little cheaper. Maintenance on permeable driveways made from paving stones can be extensive, though. First, the cracks between the pavers must be kept clear of debris if you want to facilitate the flow of stormwater.

Also, the pavers themselves need to be resealed every 5 years or so to prevent water from penetrating them. Paving stones are usually pretty susceptible to weather extremes and vulnerable to chipping and cracking as well.

2. Gravel Pavers

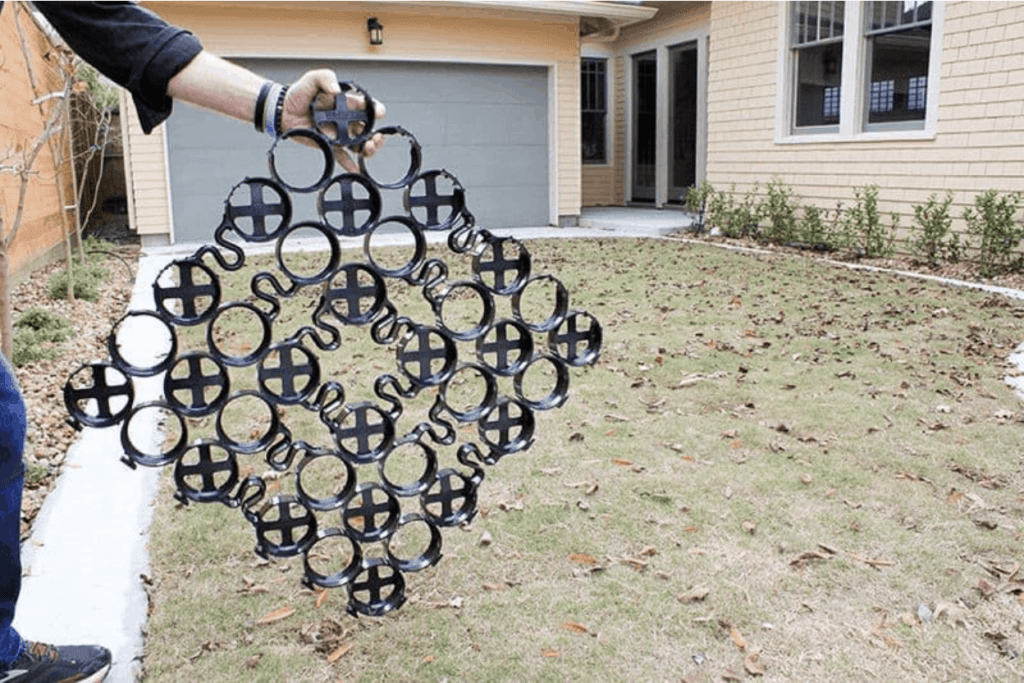

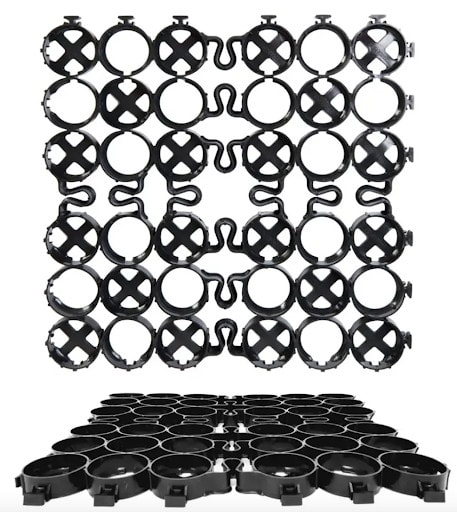

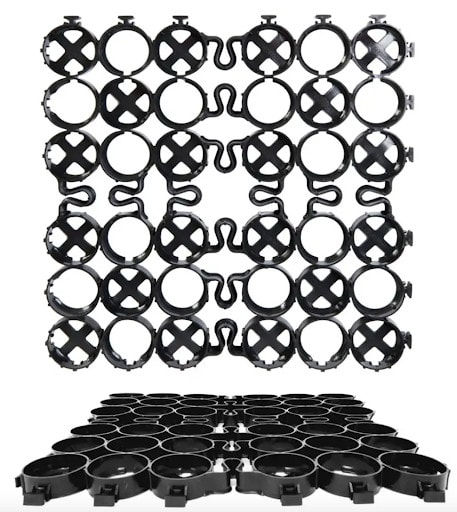

Loose gravel is a popular option for permeable driveways, but modern permeable driveways require a little more. Permeable plastic pavers like the kind made by TRUEGRID are the perfect solution for adding permeability.

Not only do these pavers provide a level, stable place to drive and park, they are 98%- permeable. Also, you don’t have to worry about gravel migration or maintenance. A driveway made from TRUEGRID PRO LITE and TRUEGRID PRO PLUS pavers can last up to 60 years with almost no maintenance required.

These pavers are also durable enough to handle the weight of a falling monster truck without breaking. Made from 100%-recycled plastic and impervious to UV-rays, weather extremes, insects, rotting, warping, and other common causes of deterioration, TRUEGRID permeable pavers are the best choice for stabilizing a gravel driveway.

Not only can the installation process for modern permeable driveways made from TRUEGRID pavers be completed in less than a day in most cases, there’s a ton of stylistic versatility available as well. You can use a wide range of different-colored gravel or pebbles to fill the surface level of your driveway, allowing for a creative, yet clean-cut look if you want it.

3. Stabilized Grass

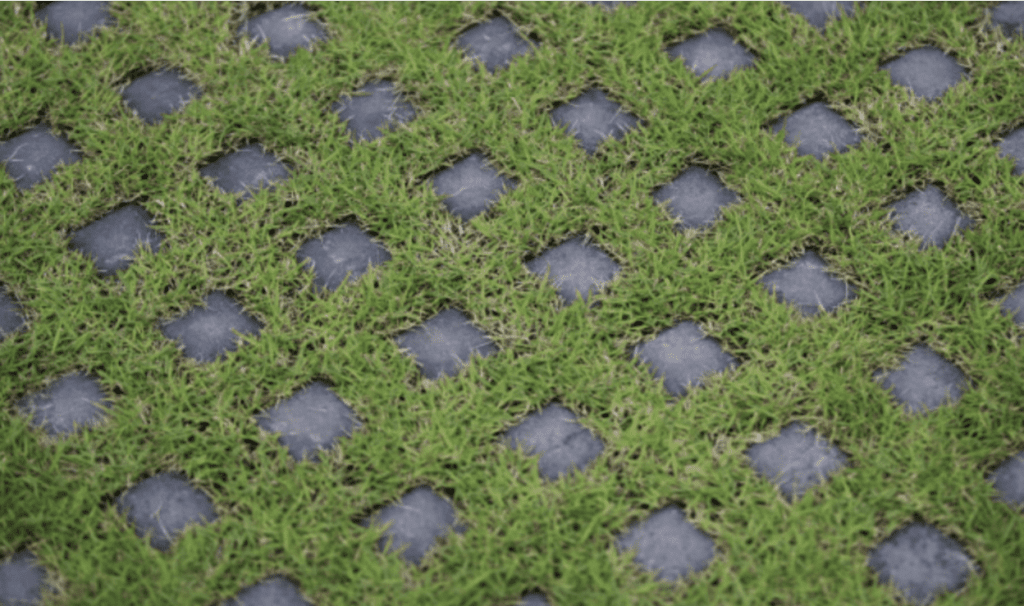

Not every driveway has to involve rocks, asphalt, or concrete. Take modern permeable driveways made from TRUEGRID ROOT pavers, for instance. These pavers are made from 100%-recycled plastic and are just as long-lasting as the other pavers offered by TRUEGRID.

The installation process is incredibly simple, with the pavers simply being rolled over the ground and driven over to compress them into the dirt. After installation has been completed, your grass will grow through the pavers and render your driveway invisible if you let it get long enough.

The resulting stabilized grass area will be able to handle vehicle traffic without rutting or shifting. It will also be almost completely permeable. This is one of the most popular new permeable driveway ideas as of late because of what it allows you to do stylistically with your driveway.

As previously stated, you could opt for an invisible driveway if you choose, or you could simply stabilize part of your driveway with TRUEGRID ROOT pavers and pave the other parts of it with stone pavers, gravel, asphalt, or concrete.

Build the Best Modern Pervious Driveway with TRUEGRID

Permeability is a major benefit if you’re building a new driveway. Even in areas not known for major storms and flooding, having a modern permeable driveway can help lower maintenance requirements, prevent erosion, and lengthen the lifespan of your driveway.

There are plenty of materials you can use to build a permeable driveway with, like loose gravel and paving stones, but nothing stacks up to a permeable driveway made with TRUEGRID pavers. Whether you want a stabilized gravel driveway, a stabilized grass driveway, or some combination of both, you’re in good hands with TRUEGRID pavers.

If you want one of the most durable, stylish, eco-friendly, and low-maintenance permeable driveways around, call TRUEGRID today to get in touch with a pavement professional for a quote.

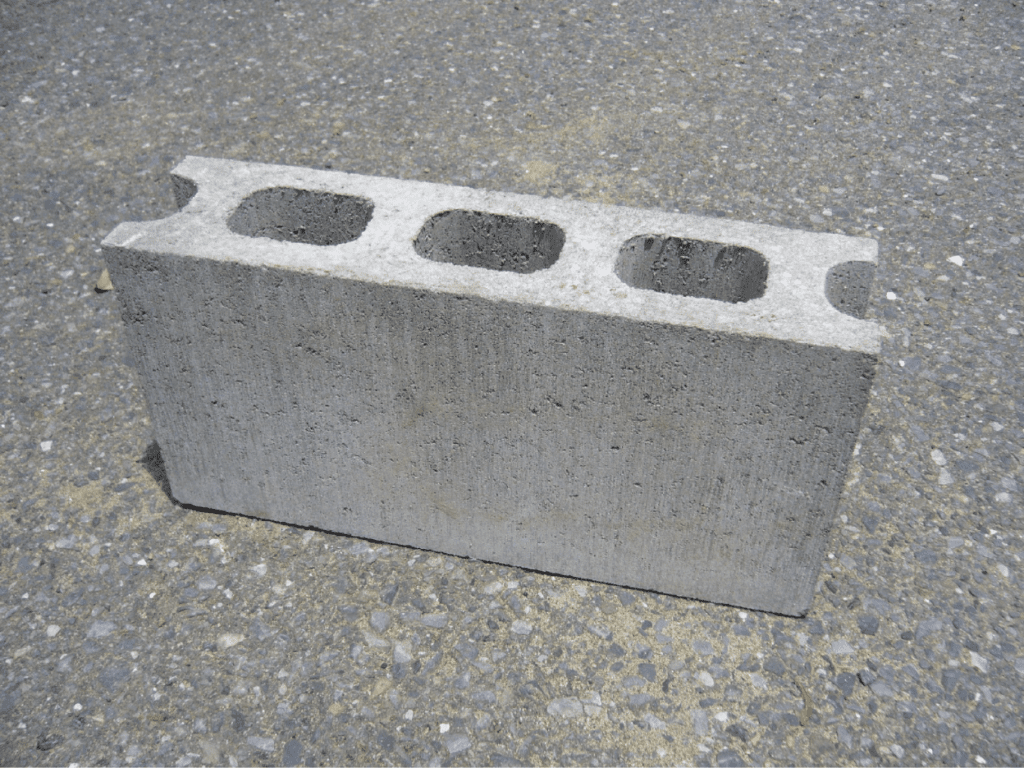

There are many different types of pavement and each has its own advantages and disadvantages. Cinder blocks, for example, are widely used as pavers by many people. Cinder block pavers are known for having unique characteristics that differentiate them from other types of cement pavement such as concrete.

Whether you’re looking for affordability, permeability, a specific aesthetic, or something else, cinder blocks have a lot to offer as a pavement material. In case you’re thinking about implementing cinder blocks in a project of some sort, let’s take a look at what they bring to the table, as well as a better alternative.

Why Use Cinder Blocks?

Cinder blocks are known for being incredibly cheap and inexpensive. They’re like a much weaker version of concrete blocks, having almost no tensile strength to withstand any significant amount of force or pressure. Cinder blocks are made using the ashes and cinders from burned wood, combined with cement. This creates lighter blocks that can be used for a variety of purposes like paving.

The main benefits of cinder blocks as pavers are their low cost and permeability. They aren’t generally stylistically diverse and typically only come in a few sizes and shapes. Cinder block pavers are great for stabilizing areas of your yard and can even be used to build a cinder block driveway.

Constructing a block driveway with cinder blocks is relatively simple. You would simply have the area excavated to a certain depth and either lay the cinder blocks right after, or lay a bed of gravel for enhanced drainage and then lay the cinder blocks on top.

Some people like to fill their cinder blocks with soil and grow grass in the open areas within each block. You can also fill the blocks with an aggregate like sand, gravel, or pebbles and use a cinder block driveway border to keep stray material from spreading.

One of the main downsides of using cinder blocks as a paving material, especially for driveways, is the low level of durability. Cinder blocks easily chip and crack and do not last very long when subjected to constant vehicle traffic. This makes maintenance and replacement a constant concern.

Replacing Cinder Blocks with a Better Choice

Building a permeable paved surface is beneficial for many reasons, and can be done with many different types of material. If you want to build a cinder block driveway border, cinder blocks do not provide as much value as permeable plastic pavers, for instance.

Permeable plastic pavers like the kind made by TRUEGRID are some of the most durable and long-lasting pavers on the planet. Made from 100%-recycled plastic, the TRUEGRID PRO LITE and TRUEGRID PRO PLUS systems are perfect for implementing a clean-cut, 98%-permeable paved surface that can withstand the weight of a monster truck falling on it without breaking.

These pavers are impervious to temperature extremes, moisture damage, erosion, UV- rays, and almost any other hazard you can think of. They will last up to 60 years with almost no maintenance required other than a quick pressure wash now and then.

TRUEGRID Pavers Outperform Cinder Blocks Across the Board

Whether you’re looking for durability, permeability, low maintenance requirements, stylistic versatility, or some combination of these traits, TRUEGRID pavers have them all without question. They are also incredibly quick to install.

The installation process is similar to that of cinder blocks but can usually be completed in as little as one day. First, the area is excavated to a depth of 12 inches, then a piece of fabric is laid at the bottom to prevent the migration of gravel. The gravel is then compacted until it’s level with the surface, at which point the TRUEGRID pavers are snapped into place over the top as easy as LEGO blocks.

Next, more gravel of your choice is poured over the top of the pavers and pressed into them, weighing them down and creating a level, durable surface to drive on. A TRUEGRID driveway or patio will eliminate flooding concerns because, with an almost 100%-permeability rate, even the heaviest storms are withstood with ease.

When it comes to eco-friendliness, TRUEGRID pavers outperform cinder blocks as well. Since cinder blocks are made from the cinders of burned trees, they are significantly less eco-friendly than TRUEGRID pavers which are made from 100%- recycled plastic.

You can also use a variety of different colors and styles of aggregate to fill the surface of your TRUEGRID pavers, allowing you a ton of creative flexibility when it comes to choosing the overall aesthetic of your paved area.

Cinder Blocks Don’t Measure Up to TRUEGRID Pavers

If you want a permeable paved surface that looks incredibly clean-cut, requires little maintenance, will last up to 60 years, and is one of the most eco-friendly paving materials on the market, call TRUEGRID today and get in touch with a pavement professional.

Pavement comes in all shapes and sizes. From asphalt to concrete, paving stones, and beyond, there’s no shortage of materials to choose from when designing your new paved surface. Asphalt and concrete may be the most popular pavement types, but many other materials are quickly gaining popularity as well.

Pebble pavers, for instance, can use any number of different pebble types to create a level and stable surface that you can walk and/or drive on. However, pebbles are still a relatively fringe material when it comes to building pavement.

In case you’re interested in utilizing pebbles to create a paved surface, here’s a complete breakdown of the benefits of pebble paving and how to effectively install them.

Why Use Pebbles for Pavement?

Pebbles have unique characteristics and advantages that make them appealing to many people. For starters, pebbles are at least somewhat permeable. Loose pebble paving is permeable to a certain degree, with larger pebbles being more permeable. When installed with TRUEGRID pebble pavers, however, pebbles can reach almost 100% permeability.

Permeability in a paved surface is great for a number of reasons. It’s the best way to manage stormwater because it eliminates the need for most, if not all, other drainage and allows water to flow naturally back into the ground like it’s supposed to. This lessens the burden on local storm systems and eliminates the need for costly maintenance on additional drainage like sewers, grates, pipes, and more.

For small-scale uses, pebble paving used in a patio or driveway can eliminate the potential for flooding and lessen the need for maintenance on or around the area due to erosion. For commercial use, using pebbles stabilized with plastic pavers can eliminate the need for on-site storage basins where stormwater is kept and stored as a means of reducing the impact on sewer systems.

Pebbles are also one of the most eco-friendly materials you can use for paving. They don’t require much heavy machinery or equipment to produce and they are recyclable as well. Their permeability is another aspect of pebbles that makes them so eco-friendly. Pebbles are also pretty cost-effective and can be obtained for incredibly cheap prices.

How to Install Pebble Pavement the Right Way

There are a couple of ways you can install pebbles as pavement. The first is to use loose pebbles and just dump them wherever you want a paved area. For driveways and patios, borders can be used to keep the pebbles from spreading too easily.

This is not the preferred way to install pebbles, though, and can require constant replacement of the pebbles as they migrate out of the designated area. The correct way to install pebbles and get the most out of them as paving material is to use pebble pavers to stabilize them.

TRUEGRID is an example of a company that makes some of the highest-quality pebble stone pavers on the market. Used in conjunction with aggregates like pebbles or gravel, they can be used to build some of the most durable, long-lasting, permeable, and low-maintenance paved surfaces on the planet.

The installation process for TRUEGRID PRO LITE and TRUEGRID PRO PLUS pebble pavers is very simple. First, the desired area is excavated to a depth of 12 inches and a piece of fabric is laid at the bottom to prevent gravel migration.

Then, the pit is filled with your aggregate of choice and compacted until level. Next, the empty TRUEGRID pavers are snapped into place over the gravel pit like LEGO blocks, and filled with pebbles.

The pebbles are then driven over and/or compacted into the surface of the pavers, filling them up and weighing them to the ground. This completes the installation process and the entire project can be completed in just one day in many cases.

TRUEGRID Will Help You Get the Most Out of a Pebble Paver Surface

TRUEGRID pavers are by far the best choice for pebble paving. Not only are they durable enough to last up to 60 years with only minimal maintenance, they are impervious to UV-rays, temperature extremes, warping, rotting, mold, and insects. They are strong enough to handle the weight of a monster truck falling on them without breaking and can be disassembled very quickly if necessary.

Many different types and colors of pebbles can be used in TRUEGRID pebble stone pavers, allowing you maximum stylistic flexibility when it comes to your pavement design. They are 98%-permeable and made from 100%-recycled plastic, making them one of the most eco-friendly paving materials in existence.

If you want to create the best-looking and most durable paved surface imaginable, TRUEGRID permeable plastic pavers should be your first choice. Don’t hesitate to call TRUEGRID today and get in touch with a pavement professional for a free quote.

When it comes to pavement, there are many different types you can use. Depending on your needs and stylistic preference, there are any number of pavement types that might perfectly suit you.

One of these types is interlocking concrete pavers. These pavers are favored by many and there are many benefits to using them. They aren’t, however, the only viable option when it comes to permeable pavement, and pavement in general.

In case you’re interested in installing some interlocking concrete pavers around your home or building, let’s take a look at what the best permeable alternative to this material is and why you’d be wise to implement it.

Why Use Permeable Pavement?

The use of permeable pavement has been around for a very long time, but it’s taken a major evolutionary jump in recent history. Thanks to companies like TRUEGRID and others, permeable pavement is now as durable, eco-friendly, cost-effective, and low-maintenance as it’s ever been.

The mitigation of flooding and management of stormwater are the main reasons why you might want to use permeable pavement. Where the threat of flooding exists, permeable pavement can eliminate it entirely. This is incredibly useful on a commercial scale, but can also come in handy as a residential homeowner.

If you have a driveway made from asphalt, concrete, or another impermeable material, permeable plastic pavers filled with gravel are the perfect way to eliminate driveway maintenance costs, increase durability, and remove the threat of driveway flooding and/or rutting.

The Downsides of Interlocking Concrete Pavers

Interlocking concrete pavers can be used to create a semi-permeable, drivable surface for your driveway, walkways, and/or patios, but they aren’t without their vulnerabilities. For starters, interlocking concrete pavers require more maintenance and are less durable.

Concrete pavement needs to be sealed and resealed every 5 years or so to prevent water from infiltrating the material. Interlocking concrete pavers of the permeable variety have spaces between them for water to pass through. This, however, compromises the structural integrity of the pavement over the long term, making it an inferior material for driveways.

Concrete is also vulnerable to freeze/thaw cycles, and interlocking pavers made from concrete are likely to chip and break eventually, meaning you’ll have to have them replaced. The main alternative to permeable, interlocking concrete pavers is permeable pavement made from plastic.

These pavers can offer the same or an even greater level of permeability without sacrificing anything in the way of style or durability. TRUEGRID PRO LITE and TRUEGRID PRO PLUS are two examples of permeable paving products that offer this superior permeability while remaining vastly more durable than concrete pavers.

TRUEGRID Pavers are the Top Alternative to Concrete Pavement

TRUEGRID makes the highest-quality permeable pavers on the planet. Not only are they made from 100%-recycled plastic, they are also durable enough to handle the weight of a monster truck falling on them without breaking. They are invulnerable to temperature extremes and will never chip, warp, or break throughout their 60-year lifetime.

Interlocking concrete pavers can be harder to maintain because they allow grass and plants to grow through them, while TRUEGRID permeable pavement has no such problems. These gravel-filled pavers create a level, sturdy surface to walk and drive on. They are unaffected by UV-rays and require next to no maintenance throughout their lifetime.

TRUEGRID permeable plastic pavers are also stylistically diverse in that you can use a variety of different-colored aggregates to fill them, allowing for quite a bit of versatility if you want to get creative. They’re also very easy to install.

The installation time of these pavers is one of their main benefits over interlocking concrete pavers. In most cases, installation can be completed in less than a day. The installation process is very simple and requires very little equipment.

First, the pavement area is excavated to a depth of 12 inches, at which point a piece of cloth is laid on the ground to prevent gravel migration. Then, the pit is filled to the top with aggregate which is compacted and leveled.

Next, TRUEGRID pavers are snapped in place over the top and filled with more gravel. Once the surface of the pavers has been filled in with gravel and compacted, this completes the installation process.

TRUEGRID Pavers are the Best Permeable Paving Solution

If you’re looking for pavement that’s stylish, durable, and permeable, interlocking concrete is not the best option. TRUEGRID permeable pavement provides an aesthetic that many prefer while also offering vastly superior durability and better permeability as well.

When it comes to permeable pavement, durability, eco-friendliness, stylistic versatility, ease of installation, and low maintenance requirements all matter. Therefore, if you want the best permeable pavement money can buy, you shouldn’t hesitate to call TRUEGRID today and get in touch with a pavement professional.