A Better Alternative to Crush and Run Driveways

Crush and run driveways, sometimes known as crusher run, dense grade aggregate, or quarry process, is a type of gravel driveway. Gravel comes in many forms and depending on what type of driveway you have, you may prefer one type over another.

What makes crush and run unique is that it’s commonly made from a combination of stone dust and pulverized stone. The stone used in this process will usually be either granite, trap rock, or limestone. When the original material has either gravel or limestone added to it, it becomes crush and run gravel.

Crush and run gravel is useful for a number of reasons. It’s cheaper than regular gravel, which is already pretty cheap to begin with. Also, the limestone sticks together when wet, to help the surface of your driveway last a bit longer.

For these reasons, crush and run is frequently used to build cheap driveways. If you want to know what a better alternative to crush and run is, let’s take a look at some of the problems with this paving material and what a better alternative may be.

The Problem with Crush and Run

The problem with building a driveway out of crush and run gravel is the same problem you’d have with any type of loose gravel, it spreads. Even with borders installed around the edges, crush and run gravel is likely to either spread outside your driveway borders, into the surrounding soil beneath the surface, or both.

This requires you constantly add more gravel, in addition to sweeping up the gravel that’s already spread. This can be rather labor-intensive and annoying, so therein lies the need for a better alternative to a loose crush and run driveway. However, if you’re wondering if crush and run is good for a driveway, the answer is yes. It just depends on how you install it.

A loose crush and run gravel driveway will also break down and deteriorate rather quickly. This can cause dust buildup to occur, in addition to rutting and mud holes. Therefore, if you want to create an effective, durable crush and run driveway, you need to stabilize it with permeable pavers.

How to Build a Better Alternative to Loose Crush and Run

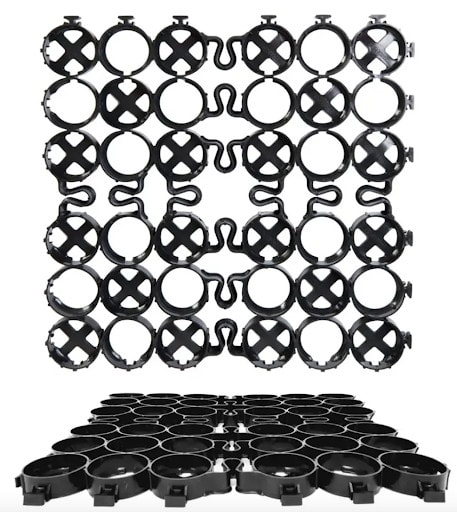

Crush and run for driveway building can work, but only permeable pavers such as TRUEGRID PRO LITE or TRUEGRID PRO PLUS can stabilize a gravel driveway for the long term. TRUEGRID pavers feature empty cells that are designed to hold the gravel and prevent it from spreading or becoming ground into dust. They provide a natural border to keep your entire gravel driveway neat, clean, and functional year-round.

Made from 100%-recycled plastic, they are 98%-permeable and will prevent your driveway from flooding, spreading, or developing ruts. They utilize a 12-inch sub-base of dense gravel to drain stormwater directly through them while keeping the surface-level gravel firmly intact.

Using TRUEGRID permeable plastic pavers is actually the cheapest way to keep a gravel driveway because it lowers the amount of maintenance you have to do and prevents you from ever having to buy more gravel.

TRUEGRID is the Superior Alternative to Loose Crush and Run

The permeable pavers from TRUEGRID are the best solution for stabilizing gravel of any kind to use in your driveway. The installation process is very simple and involves excavating the driveway to a depth of 12 inches before laying a piece of fabric at the bottom to prevent the migration of gravel.

Next, the excavated area is filled with gravel and compacted, before the empty pavers are snapped together in place over the top. Once this is done, more gravel of your choice is poured over the top and compressed into the pavers with a vehicle or heavy roller. This weighs the pavers down and prevents the surface of your driveway from shifting or moving at all.

The durability of a loose crush and run driveway is next to nothing, but with TRUEGRID pavers you can improve the durability and extend the lifespan of your gravel driveway up to 60 years before needing replacement. With some light sweeping and a good spray-down every now and then, it should be no trouble at all to maintain your TRUEGRID permeable paver driveway.

Other popular materials for use with TRUEGRID pavers include stone, pebbles, and even grass. TRUEGRID ROOT pavers, for example, can turn a regular yard into a stabilized driveway, as the grass will take root and cover the paver grids.

Let TRUEGRID Help You Get the Most Out of Your Crush and Run Pavement

Crush and run is popular for a variety of reasons, but when combined with TRUEGRID stabilizing pavers, all of its good qualities are maximized while its negative qualities are minimized. TRUEGRID pavers are impervious to temperature extremes, UV rays, wind, rain, and insects.

If you want the best crush and run driveway money can buy, don’t hesitate to call TRUEGRID today and get in touch with a pavement professional who can point you in the right direction.

If you’re looking for a new type of pavement to use instead of asphalt or concrete, permeable pavers are a great option. Permeable pavement has exploded in popularity lately and innovations in paving tech have resulted in pavers that are more durable, eco-friendly, and affordable over the long term.

Permeable pavement is also becoming a favorite because of the need to mitigate flooding in paved areas. As storms become more violent and certain areas suffer from increased levels of heavy rainfall, flooding is now a very real danger for people who never used to think twice about it. Flooding can destroy property and take lives, so the 98%-permeability of TRUEGRID permeable pavers, for instance, can come in handy.

Pavers like these not only drain stormwater much more effectively than traditional stormwater management methods, they also eliminate the need for additional costly drainage. Permeable pavers are better for the environment, easier to install, more affordable, and more effective at providing a stable, long-term parking solution for just about anyone.

One of the main benefits of permeable pavers is their lack of maintenance requirements. The level of maintenance required to keep permeable pavers in good shape is so low and affordable that it often feels like nothing at all in comparison to resurfacing or resealing other types of pavement about every 5 years.

There are, however, a few different ways you can care for your permeable pavers when the situation arises. In case you want to know all the tips and tricks for keeping your permeable pavers clean, let’s take a look at some maintenance tips.

How to Care for Your Permeable Pavers

1. Sweeping

Although permeable paver maintenance doesn’t need to be carried out very often, you should perform a bit of upkeep now and then. The simplest thing you can do to keep your pavers clean is to unclog them of trash and debris.

Anything you can see on the surface and pick up needs to be removed. Twigs, trash, leaves, and other debris can clog your pavers so using a broom and/or your hands to clear debris is a good idea.

2. Inspection

Inspecting your pavers at least 3 times a year after heavy rain is another important part of a permeable paver maintenance plan. Look for pooling water and visible dirt or material in the gaps between your pavers. This is an indication that you may have a clog beneath the surface.

During an inspection, you’ll also want to look for signs of wear and tear that may indicate your pavers need to be resealed. For paving stones and bricks, this is a critical part of preventing water infiltration and further damage.

3. Vacuuming/Power Washing

The most intensive part of a permeable paver maintenance guide involves vacuuming. When your pavers have a serious clog or something you can’t fix with basic tools like a broom, that’s when it’s time to bring in the heavy artillery.

Using a shop vacuum (6hp or better) two times per year is the best way to keep your pavers as unclogged as possible. One tip is to use a nail or a screwdriver to loosen up the packing between your pavers to facilitate better cleaning before you vacuum.

If you use granite chips between your pavers, you’ll likely suck some of them up during the vacuuming process, which is fine. After you’re done vacuuming, simply wash the chips off and put them back into place.

If you have permeable pavers filled with gravel like TRUEGRID PRO LITE or TRUEGRID PRO PLUS, you’ll want to power wash them instead. Use a garden hose to aim a direct spray at the pavers. This should help to clear out any dirt clumps and get things moving regularly again.

4. Snow and Ice

Snow and ice are usually not much of an issue for permeable pavement. The snow tends to melt and disappear through the pavers, while ice does need to be dealt with. You should remove as much snow from your permeable pavement as you can after each snowfall.

For ice, you can use salt as long as you don’t use too much. Permeable pavement requires less salt to remove ice, and many types will deteriorate if you use too much. You can also lay down some grit for traction, just don’t use sand. Sand will clog your pavers, so use gravel or small stones instead. You can always sweep it up later.

Caring for your Permeable Pavers is a Breeze

One of the upsides of permeable pavement and permeable plastic pavers, specifically, is that they require very little maintenance throughout their lifetime. Sweep every so often, inspect them after heavy rains, and vacuum or power wash them 3 times a year.

If you’re looking for permeable pavement that will last you up to 60 years with minimal maintenance required, call TRUEGRID to get in touch with a pavement professional today.

A high school is often the center point of a community, or at least a prominent hub of activity and a representation of the town or city it’s located in. That’s why it’s more important than you might think that your local high school looks as inviting, creative, and innovative as possible.

Having a beautiful high school facade makes the place stand out, and can even entice people looking for a place to move, especially if they have kids. And, while most high schools use landscaping features, signage, and exterior additions to the school itself as a means of improving curb appeal, the parking lot is usually overlooked.

Most high school parking lots are made from asphalt, which is a cost-effective, yet bland and temporary solution for parking. Asphalt parking lots are the norm in America which is why there’s a lack of innovation and creativity surrounding parking spaces.

However, there are options available now that are more stylish and cost-effective than asphalt, like permeable pavers. So, in case you want to update your high school parking lot, let’s look at 3 great ideas for how to do so with permeable pavement.

Why is Permeable Pavement Better for High School Parking Lots?

Permeable pavement like the kind made by TRUEGRID is one of the best high school parking lot solutions for many reasons, the first being durability. High school parking lots see more wear and tear than almost any other type of parking lot. This causes the asphalt to break down at a rapid rate and the lots need to be resurfaced and replaced more frequently than they normally would.

Since asphalt is impermeable, these lots often deal with flooding or they have to implement additional drainage features like sloping and trench drains to deal with stormwater. When the lots inevitably break down, potholes can wreak havoc on the vehicles of young drivers.

TRUEGRID permeable pavers, on the other hand, will last up to 60 years with only minimal maintenance required for upkeep. They’re also 98%-permeable, and allow all stormwater to drain directly through them, eliminating the need for additional drainage as well as the possibility of flooding.

These pavers are made from 100%-recycled plastic, making them one of the most eco-friendly high school parking lot solutions on the market. They can also utilize a variety of different colored gravel to create unique and varied looks, designs, and aesthetics in a high school parking lot.

The Best Permeable High School Parking Lot Options

1. Gravel

Gravel is incredibly cheap and when combined with stabilizing pavers like TRUEGRID PRO LITE or TRUEGRID PRO PLUS, it makes for the single most cost-effective yet durable parking lot solution available. The pavers themselves can be cut to size and fit into just about any space you need them to.

Gravel also comes in a variety of colors which can be used to create vivid patterns and visually appealing color schemes throughout your lot. Gravel is best used in a high school parking lot that gets a lot of traffic and needs to mitigate maintenance requirements.

2. Grass

This is one of the coolest high school parking lot solutions you’ll come across. TRUEGRID ROOT pavers can be used to turn any grass area into a parking lot, without displacing the grass. Simply roll these pavers right out onto the grass and press them into the ground with a vehicle or heavy roller.

They will grip the soil and stay firmly in place, stabilizing the surface to be driven on and preventing ruts or mudholes from developing. TRUEGRID ROOT also allows the grass to grow right up through the pavers themselves, meaning you could maintain an invisible parking lot if you let the grass grow high enough.

3. Combination

You can also use TRUEGRID permeable pavers to implement a combination parking lot. This might mean using other materials like asphalt in conjunction with permeable pavement.

You could also implement both TRUEGRID ROOT and TRUEGRID PRO LITE or PRO PLUS pavers to stabilize your entire lot while still keeping some grass around as well. You could also use small stones in the pavers instead of large gravel. This presents a different look and can provide you with even more variety as far as colors go.

TRUEGRID Can Revolutionize Your High School Parking Lot

High schools are places of innovation and excitement, so why not let your parking lot reflect that? TRUEGRID permeable pavement is one of the most innovative, durable, stylish, eco-friendly, cost-effective, and low-maintenance paving materials in existence.

If you’re ready to do away with your boring old asphalt lot and replace it with something that really catches the eye and cuts costs as well, why not go with one of the most durable and stylish high school parking lot solutions you can find? Call TRUEGRID today and get in touch with a pavement specialist who can get you pointed in the right direction.

Patios are all the rage nowadays, and with so much emphasis being placed on home renovations lately, patios remain one of the most popular home improvement projects you could complete.

One of the things that make patios so great is that they’re incredibly customizable and you can create a unique patio that stands out from your neighbors with ease. In fact, the number of patio materials to choose from is so vast it can be hard to choose, that’s where patio kits come in.

Patio kits are pre-packaged kits with all the supplies you need to create a DIY patio in your yard. They can come with any number of different types of patio layouts and are generally the quickest way to install a patio.

In case you’re looking for a great patio kit to install as the weather warms up, let’s take a look at patio kits and why permeable pavers are the best type of kit to use.

Why Use a Patio Kit?

Patio kits are the perfect choice for a first-time DIY project or just a super fast install, in general. Installing one of these paving patio kits is a great choice if you’ve prioritized price, simplicity, and speed in your patio installation.

When sourcing all your patio materials separately, there’s a lot that goes into it. If you’re hiring professionals to build it, you need to call and get a quote on the price of the overall project. If you’re sourcing all the materials yourself, you’ll need to run through an entire checklist of things you need to install your patio properly.

Then, you’ll have to install the patio without any set list of instructions. Doing the labor yourself can lead to the project taking a lot longer than it should, and you may even end up with some surplus supplies.

What Type of Patio Kit is Best?

Patio kits can be found in any common paving material you can think of, and come in an endless variety of colors and shapes. The stones themselves can be shaped any which way and can even have different engravings or graphics printed on them.

However, paving stones are not the best material for patio paving kits, especially if you’re looking for cheap patio paving kits that will last a long time. Paving stones and bricks are not a great option.

These materials need to be resealed every so often and are prone to temperature extremes, cracking, and chipping. Not only that, but circle patio paving kits made from primarily brick and/or stone are more expensive than ones made from a superior material like TRUEGRID permeable pavers.

What Makes TRUEGRID Pavers the Best Option for a Patio Kit?

1. Eco-Friendliness

TRUEGRID PRO LITE and TRUEGRID PRO PLUS pavers are perfect for garden patio kits or any other type of patio you want to build for a variety of reasons. For starters, they are made from 100%-recycled plastic, making them one of the most eco-friendly patio kits on the market.

2. Permeability

Patio paving kits made from TRUEGRID permeable pavers are also 98%-permeable, meaning they will drain stormwater directly through their surface and into the ground below. This keeps erosion and flooding from occurring, and can extend the lifespan of your TRUEGRID patio up to 60 years before needing replacement.

3. Ease of Installation

TRUEGRID permeable pavers are also the best patio paving kits because of how easy they are to install. With other materials, you’ll likely need many different pieces of equipment and other things to complete the job, but not with TRUEGRID pavers.

All it takes to install circle patio paving kits and other types of patios with TRUEGRID pavers is a basic excavation of about 12 inches. Once the excavation is complete, a piece of fabric is laid at the bottom of the pit to prevent gravel migration. Then, the empty pit is filled with gravel and compacted until level with the ground.

Next, the empty TRUEGRID pavers are snapped into place over the top and filled with gravel before being driven over with a vehicle or heavy roller. Once the gravel has been compressed into the surface of the pavers, the installation process is completed.

The Best DIY Patio Kit is Made from TRUEGRID Pavers

If you want the easiest patio kit to install without having to sacrifice style, permeability, eco-friendliness, or durability, TRUEGRID permeable plastic pavers should be your go-to choice for paving material. These pavers snap together like LEGO blocks and can be installed in less than a day in most cases.

If you’re looking for one of the longest-lasting, low-maintenance, permeable patio paving kits out there, don’t hesitate to call TRUEGRID today and get in touch with a pavement professional for a free quote.

Almost every commercial business in America uses pavement of some sort. Pavement plays a vital role in building the sidewalks, pathways, driving lanes, and parking lots that accompany most buildings. There are many different types of pavement, all with their own strengths and weaknesses.

Depending on what kind of pavement you choose for your business, you can expect different maintenance requirements, installation costs, stylistic variety, durability, and other outcomes that can have a big impact on your business.

Getting your pavement right is very important, so let’s go over a complete breakdown of everything you need to know when it comes to commercial paving.

Common Types of Commercial Pavement

The most commonly used commercial paving materials are asphalt and concrete. The majority of parking lots and other paved areas around businesses are built with one or both of these materials. There is also permeable pavement, which combines pavers with aggregates like gravel to provide a stable, 100% permeable surface.

For pathways and other small paving needs, bricks, quartz,marble, and other options are available as well.

Asphalt

The most common type of asphalt is dense-graded asphalt, also known as hot-mix asphalt. There is also porous asphalt, which is semi-permeable and allows a certain amount of water to drain through it. Though not as effective as and much more fragile than permeable pavement, porous asphalt can help reduce splashing as well as tire noise.

Another type of asphalt pavement is known as “tar and chip”. This is a less refined version of asphalt and uses crushed gravel compacted into still-wet asphalt. Tar and chip pavement has a rough surface and doesn’t hold up well in extreme temperatures. It also unravels easily, leading to higher maintenance costs in the long-term.

For this reason, hot-mix asphalt combined with a drainage system of some sort is what most business owners use for commercial paving. A hot-mix asphalt parking lot can cost anywhere from $10,000 to $700,000 to install, depending on the size. The average asphalt lot costs about $75,000 to install.

Asphalt lot maintenance is extensive. To keep your asphalt lot in top shape, it needs to be repaved every 10 to 15 years, which can cost up to $2.50 per sq ft. If your lot needs to be resurfaced, that will cost up to $5 per sq ft. There is also the cost of lot striping, sealcoating, parking lot lights, and other miscellaneous factors to consider, such as snow removal.

Lot stripes cost about $5 per every 18 feet of striping. Sealcoating costs about $0.25 per sq ft. Lot lights can cost over $1,000 per light. Bumpers cost around $100 a piece, and spot sensors can cost as high as $600.

The load capacity of asphalt is less than that of concrete or permeable pavement, so you need a thicker lot if you want it to be able to handle heavy traffic and bigger vehicles. In hot climates asphalt does not wear well. Asphalt is almost entirely limited to black, with yellow or white lot lines.

A drainage system such as a sloped lot, and drains leading to local city sewers, is also required for an asphalt lot. The price is about $35-$45 per linear foot. Some businesses are required to have an entire water detention pond, which costs even more.

Concrete

Concrete is stronger than asphalt, but more expensive as well. There are a wide variety of different types of concrete, but most of them are used in very specific situations and not for general commercial paving. The main type of concrete used in commercial paving is standard ready-mix concrete.

The average concrete lot costs around $4-$7 per sq ft to install, which includes the cost of both labor and materials. Concrete needs to be resealed every 2-5 years, which can cost up to $2 per sq ft. Resurfacing concrete to extend its lifespan beyond the expected 30-40 years will cost up to 5$ per sq ft.

Pervious concrete and asphalt still need additional drainage to handle all the runoff they get from storms.Pervious concrete clogs easily and needs frequent vacuuming with specialized equipment to maintain its porosity. e. A concrete parking lot drainage system costs about the same as an asphalt drainage system. Pervious versions of asphalt and concrete can reduce the need for drainage, but not eliminate it.

Average asphalt and concrete parking lots can take anywhere from 2 to 4 weeks to complete. Concrete is stylistically limited, but offers more options in terms of graphics and markings that can be painted onto its surface.

Permeable Pavement

Permeable pavement is a commercial paving option that is taking the world by storm right now. It’s superior to asphalt and concrete in terms of durability, cost, installation time, maintenance requirements, eco-friendliness, and overall efficiency. Some companies, like TRUEGRID, make 100% recycled plastic pavers, which is one of the most eco-friendly paving materials you’ll find anywhere.

A permeable paver parking lot can be completed in a few days, costs less per sq ft to install. It requires only a basic excavation, a simple snapping-together of the pavers, and a compaction of the aggregate into the surface of the pavers with a heavy vehicle.

TRUEGRID permeable paver lots require no additional drainage because they allow liquids to drain right through them and into the soil below. This reduces the burden on local stormwater systems and allows commercial business owners to use 100% of their allocated land for parking, rather than having to incorporate drainage as well.

TRUEGRID pavers are more durable than asphalt and concrete in the short and long-term. Their load capacity is rated H20 and H20+ allowing them to handle the heaviest vehicles with ease.

The cost to install a TRUEGRID permeable paver commercial lot is up to 50% less than the cost of concrete. It costs about the same as it does to install an asphalt lot, but with almost none of the associated maintenance costs.

Permeable pavers from TRUEGRID will not contribute to a “heat island” effect and can even get you LEED points. Gravel-filled pavers are also much easier on the axles and wheels of fleet vehicles, leading to lower long-term maintenance costs for them as well.

TRUEGRID also offers SnowSpots™, SuperSpot® parking markers, reflectors, and stepping-stone pavers for your various needs when it comes to design and safety.

The Right Commercial Pavement Strategy Can Go a Long Way

Whether you opt for asphalt, concrete, or permeable pavers, making the right decision for your business parking lot is crucial. In addition to planning for optimal traffic flow and a lower risk of accidents occurring, you also need to decide whether you want permeable or impermeable commercial paving.

Impermeable or semi-permeable pavement like asphalt and concrete require frequent maintenance and additional drainage systems as well. Permeable pavers from TRUEGRID are a non-traditional look, but they offer superior durability, stylistic diversity, affordability, and eco-friendliness.

For more information on permeable pavers and a custom quote for your commercial project, contact a paving expert at TRUEGRID today.