How to Design a Permeable Handicapped Parking Space

If you’re building a parking lot, you’re going to need to include some handicapped parking spaces. You’re required by law to have them and they can make life a lot easier for disabled customers and visitors. However, one of the main concerns of building and maintaining a handicapped parking space is keeping it maintained.

Preventing cracks, ruts, and potholes from developing in and around a handicapped parking space is crucial. You don’t want someone with some sort of physical disability to worry about navigating potholes and puddles, because not only is it more dangerous for them, it can make for an unpleasant experience.

Adding handicapped spaces to a parking lot is about making the experience easier for disabled people, so the last thing you want is them getting wet or injured on their way into the building. For that reason, permeable handicapped spaces are the best choice for owners who want to maintain a durable, high-quality parking option for disabled individuals.

In case you’re building a new lot or just looking to add handicapped parking spaces to your existing lot, let’s take a look at how to design a permeable handicapped parking space.

Requirements for Handicapped Parking Spaces

There are special requirements for handicapped parking spaces that you need to follow to stay within code. For starters, the ADA states that all new buildings and facilities, as well as altered areas of existing buildings need to be handicapped accessible.

For parking lots with 1-25 regular spaces, you need at least one handicapped parking spot. For lots with 26 to 50, regular spaces you need to have at least 2 handicapped parking spots. For 51-75 regular spaces, you need at least 3 handicapped spaces. For 76-100 regular spaces, you need 4 handicapped spaces.

For 101-150 regular spaces, you need at least 5 handicapped spaces. For 151-200 regular spaces, you need at least 6 handicapped spaces. For 201-300 regular spaces, you need at least 7 handicapped spaces. For 301-400 regular spaces, you need at least 8 handicapped spaces and for 401-500 regular spaces, you need at least 9 handicapped spaces.

For 501-1000 regular spaces, you need at least 2% of your spaces to be handicapped spots. For 1,001 spaces or more, you need at least 20 handicapped spots and another handicapped spot for every 100 spaces you have over 1,000.

Also, every handicapped spot you have needs to be at least 60 inches wide. 1 out of every 8 spots should also be labeled as van accessible. These spots need to be at least 96 inches wide and have a vertical clearance of at least 114 inches. Each handicapped spot also needs to have a vertical signpost indicating that the spot is handicapped.

In addition to this, it also needs to have a marking on the spot itself that differentiates it from the other parking spots. This is typically done by painting the spot a bright blue color with a white handicapped sign in the middle. Color schemes can vary but should involve a neutral color contrasted with a bright color.

Optimizing Your Handicapped Spots

Aside from meeting all the guidelines and regulations, there are other ways you can optimize your handicapped parking spots. Building them out of permeable pavement instead of asphalt, for example, is the best way to do this.

Asphalt is impermeable and costly to maintain. It’s somewhat durable but needs constant maintenance to remain so. Concrete has the same pros and cons as well. It’s durable, but impermeable and in need of regular costly maintenance. You also have to keep repainting your handicapped spots as the paint wears off.

By building your handicapped spots with a product like TRUEGRID permeable pavers, you can get the most use out of them. TRUEGRID pavers trap gravel beneath them to create a level, durable driving surface that’s 100%-permeable.

TRUEGRID DECK pavers are durable and long lasting with minimal maintenance required. They are much cheaper to maintain over their lifetime, compared to asphalt or concrete. Since they’re made from 100%-recycled plastic, these pavers are eco-friendly to boot.

TRUEGRID DECK pavers are attached to TRUEGRID PRO PLUS pavers in pre-assembly, to provide a gravel-free handicapped parking option while still retaining the incredible permeability and durability of the PRO PLUS pavers.

TRUEGRID Pavers are the Best Choice for Handicapped Spots

Marking your handicapped spots can be time-consuming and costly as you repaint them again and again. However, with TRUEGRID, all you have to do is install TRUEGRID DECK pavers once and you’re good to go.

The installation process for these pavers requires very little equipment and a basic excavation. It can be completed in less than a day in most cases. The 100%-permeability of TRUEGRID pavers means that each of your handicapped spots will be invulnerable to potholes and flooding as well.

The installation process for these pavers requires very little equipment and a basic excavation. It can be completed in less than a day in most cases. The 100%-permeability of TRUEGRID pavers means that each of your handicapped spots will be invulnerable to potholes and flooding as well.

It’s safe to say that if you want to build the highest-quality handicapped parking spots possible, TRUEGRID pavers are an excellent choice. If you want handicapped spots that are immune to flooding, more durable than asphalt or concrete, and cost less to maintain, get in touch with a pavement professional at TRUEGRID today for a free quote.

If you have dirt pathways running through your commercial landscape, chances are they get muddy when it rains. Dirt pathways can often seem like an inexpensive and convenient solution to paving when you’re building pathways on your landscape, but rain can get them extremely messy in a hurry.

This might be fine for your backyard or another residential use, but for a commercial business, it’s a bad look. You don’t want sloppy, muddy trails running through your property because they muck up people’s shoes, track mud into your building, and generally look unprofessional.

So, to optimize your commercial landscape pathways, you need paving. But, with so many different types of pavement out there, it can be hard to make the right choice for your landscape. Luckily we’ve got you covered. In case you’re looking for a way to upgrade your muddy pathways, let’s take a look at some of the best solutions.

Asphalt

Asphalt is one of the most common paving materials, and for good reason. It’s cheap, relatively durable, and looks great as a finished product. Unfortunately, there are some downsides to using asphalt as well, rendering it one of the less desirable muddy path solutions. Maintenance, for starters, can be rather costly.

Over the 15-30 year lifespan of asphalt, you need to reseal it every five years and resurface it every 10. Resealing, and especially resurfacing are both costly, labor-intensive projects that can take days to complete. Asphalt also has vulnerabilities to weather and water. Freeze/thaw cycles can create cracks that widen over time.

Hot weather makes asphalt sticky as well, and foot traffic can cause an unraveling of the gravel in the top layer of your asphalt path. All of these things speed up the maintenance timeline for your asphalt and bring it to ruin if not addressed.

Concrete

Another one of the most popular muddy path solutions is concrete. Concrete is more expensive than asphalt and takes longer to install. It offers a different aesthetic appeal, and is available in white, off-white, and grey colors, most often. It can also be stamped with designs, graphics, or even patterns that make it resemble other types of pavement.

Concrete does have a lot of the same issues as asphalt, though. Although it’s not vulnerable to hot weather, cold weather makes concrete brittle and more likely to crack. Freeze/thaw cycles also take a toll, paving the way for water to infiltrate the surface and cause major damage. In addition, concrete needs the same type of maintenance that asphalt does, and just as often.

Concrete also takes an incredibly long time to install compared to most other paving materials. This is because it needs multiple curing sessions where freshly poured concrete is given time to dry before any further work is performed on it. You could order premade concrete slabs, but that option is more expensive as well.

The Importance of Permeability

A major downside to both concrete and asphalt, as well as materials like stone pavers and bricks, is that they’re impermeable. These types of materials do not let water pass through them and thus, need some way to manage stormwater.

For stone pavers and bricks, you can make the spaces in between them permeable by filling them with sand so that water can drain into a sub-surface layer of gravel that allows the water to naturally trickle back into the soil, as nature intended.

Asphalt and concrete can be found in semi-permeable varieties that allow water to drain through them at a very slow rate. These materials are even less durable than regular concrete and asphalt, though, and are easily clogged by debris.

TRUEGRID Permeable Pavers are the Optimal Solution for Your Muddy Pathways

Of all the muddy path solutions, permeable plastic pavers are the best. For commercial pathways, pavers like those made by TRUEGRID come with all the benefits you need and none of the issues that concrete and asphalt do. They cost about the same to install, but installation is easy, and takes a fraction of the time that it does with most other paving materials.

TRUEGRID PRO LITE and TRUEGRID PRO PLUS pavers are perfect for walkways on commercial landscapes because they can last up to 60 years with almost no maintenance required. They are vastly more durable than asphalt, concrete, stone, and brick, and have no vulnerabilities to extreme weather or freeze/thaw cycles. They don’t need to be sealed and are resistant to insects, UV rays, and any other potential deteriorating factor you can think of.

One of the best things about TRUEGRID pavers, and something that sets them apart is the fact that they are 100% permeable. This allows them to handle even the heaviest of rainstorms with ease, by effortlessly draining water directly through them and into a gravel sub-base.

The installation process for TRUEGRID pavers is simple, and requires no heavy equipment other than a heavy roller and a mini-excavator. First, the pathway is excavated to a depth of 6 inches before fabric is laid at the bottom to prevent gravel migration.

Then, the base aggregate is spread and compacted. Next, TRUEGRID pavers are snapped into place over the top as easily as LEGO® blocks and filled with more gravel. After the gravel has been settled into the empty cells of the pavers, the installation process is complete.

Take Your Commercial Pathways to the Next Level with TRUEGRID

Traditional muddy path solutions like asphalt, concrete, brick, stone, or others can be tempting to implement in your commercial pathways. But TRUEGRID is the best way to clean up a muddy dirt pathway.

If you want to eliminate maintenance concerns, save money in the long run, and build gorgeous clean-cut pathways that have no issues with mud, call TRUEGRID today to get in touch with a pavement specialist who can point you in the right direction.

Parking spaces can be found anywhere you look, in any town. Most of them are relatively uniform in their dimensions, but their size and shape can vary in accordance with local regulations and laws.

There are a number of different factors which might influence the dimensions of a particular parking space and there are plenty of considerations to be made when designing one. If you’re looking to optimize the parking spot in a variety of ways that benefit you and your community, considering all your options when designing a space is a wise choice.

In case you’re designing one or more parking spaces, let’s take a look at the average dimensions of parking spaces and how you can best design yours for optimal performance.

All About Parking Space Dimensions

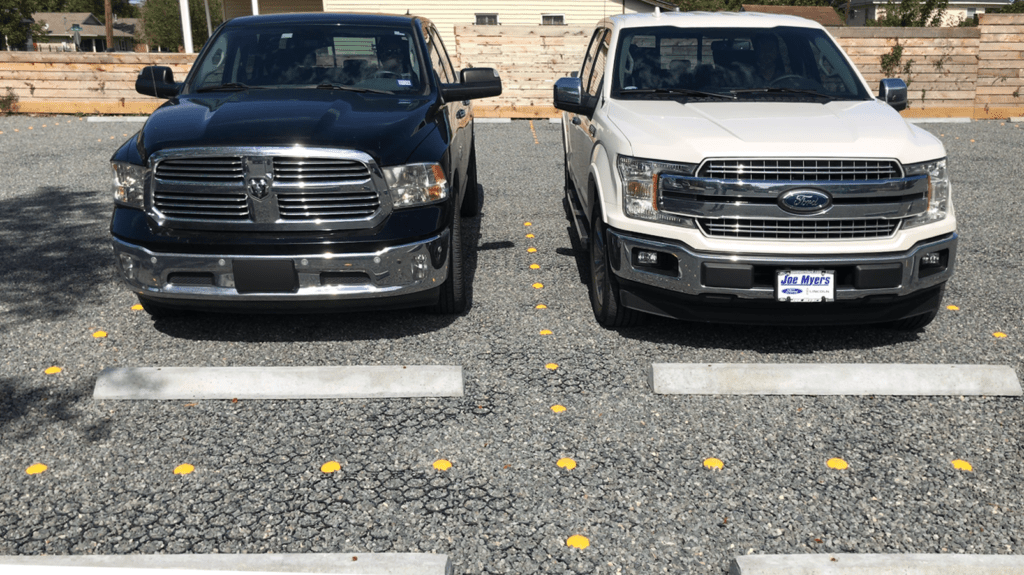

What is the size of a standard parking space? The standard parking space size in the U.S. is approximately anywhere from 7.5 ft. wide to 9 ft. wide. It’s also anywhere from 16 ft. to 20 ft. deep. These parameters are enough to accommodate the average vehicle, not including longer or wider vehicles like RVs, semi-trucks, and other bigger vehicles.

For parallel parking, the size of a standard parking space is anywhere from 20 ft. to 24 ft. deep, with a traditional 7.5 to 9 ft. width. Parking lots have additional considerations to make when designing their lots.

For areas that get a lot of traffic, the parking lot must be designed to accommodate the maximum expected amount of vehicles at one time. Though, this often results in businesses designing parking lots with too many spaces that just sit empty all the time. These large lots cost even more to maintain and can require tons of additional drainage systems past a certain size, as well.

The standard size parking space can also play a role in what angle parking spaces are set at. The goals of a particular parking space can vary and the angle of said space should be adjusted accordingly. 90-degree angle parking spaces are the most common type, and they are used as a way to save space and money. They can fit the most vehicles into the smallest area, but make maneuvering much harder.

This means people will have to take more time getting in and out of the parking space and will have to drive slower as a result. This is not always a bad thing, though, and can actually be implemented as a safety measure, forcing drivers to be more careful in an area where there are people walking in close proximity to moving vehicles.

The discussion of angles adds a bit more nuance to the equation when we ask, “What is the standard size of a parking space?” There are also other common parking space angles like 30-degree angles, 45-degree angles, 60-degree angles, and straight angles.

These angles provide more room to maneuver and make sideswipes less likely as well as lessening the instance of vehicles parking too close to each other and blocking in doors.

Additional Parking Space Design Considerations

Durability and permeability are a few more characteristics of parking spaces that we often tend to overlook. This is because they are directly related to the materials used to build a parking lot, with asphalt being the primary material that most people use.

Asphalt has a set level of durability and base level of maintenance required to keep it in top shape. It also has no permeability whatsoever, which means it requires an added drainage system to manage stormwater. Concrete is the same and though there are permeable versions of both asphalt and concrete, they are costly, easily clogged, and require a lot of maintenance.

How to Build the Optimal Parking Space with TRUEGRID Pavers

The optimal parking space should be designed with its usage in mind. If you need to fit as many spaces as possible in your lot and it’s for a bigger business like a grocery store, 90-degree angles are perfectly fine. For parking lots that don’t expect as much traffic or if you just want to make things easier on drivers, wider angles are best. Straight angles are best for parking on the side of roads.

For permeability and durability, we recommend TRUEGRID permeable pavers. TRUEGRID PRO LITE and TRUEGRID PRO PLUS, for example, both make excellent choices. These pavers are 100% permeable, and they eliminate the need for additional drainage and the possibility of flooding, as well as the need for costly maintenance.

You can also use TRUEGRID SuperSpots® to mark your parking spaces and easily shift them around as you see fit. They easily snap in and out of place instantly and never need to be repainted like traditional lot lines.

TRUEGRID pavers are so durable that they can last up to 60 years with almost no maintenance required. They are eco-friendly and made from 100% post-consumer high density plastic, using grids that snap together like LEGO blocks and lock gravel into place to create a sturdy, level driving surface.

If you want to build the best, longest-lasting, most eco-friendly parking space you can while saving money in the long run, contact TRUEGRID today to get in touch with a pavement professional for a free quote.

If you’ve ever owned a parking lot designed for tractor-trailers, you know that the weight of these enormous vehicles takes a serious toll on the pavement they park on. This is one of the reasons why tractor-trailers are banned from parking in so many areas and it makes the need for appropriate tractor-trailer parking that much more important.

Designing the perfect parking lot for a tractor-trailer isn’t as simple as it may seem, however. Aside from requiring unique dimensions and parking spaces, these lots also need to be as durable as possible so that you aren’t faced with the cost of constant upkeep and repairs.

In case you need a new parking lot for tractor-trailers, let’s take a look at the various materials used to build these lots and what might be the best choice for you.

Common Materials Used for Building Tractor-Trailer Parking Lots

Asphalt

Asphalt is far and away the most common material used when building parking lots of all shapes and sizes. This rings true for tractor-trailer parking lots as well, though it’s not necessarily the best choice. Some of the benefits of asphalt include the fact that it is somewhat durable..but not under tractor trailer loading, rather affordable, and can make for a nice parking lot for up to 5 years before it needs major maintenance.

The cons of asphalt outweigh the pros, unfortunately. Asphalt needs to be resealed every 5 years or so. This involves spreading one or more coats of sealant across the entire lot and letting it dry.

Asphalt also needs to be resurfaced every 10 years or some, which involves the removal and total replacement of the top layer of your asphalt lot. This is as labor intensive as it sounds, and costly to boot. This maintenance can take days or even upwards of a week to complete.

Asphalt is also an impermeable material, meaning water cannot pass through a regular asphalt parking lot unless it’s of the pervious variety. Both pervious asphalt and concrete aren’t suitable for the intense weight and pressure of tractor-trailers, however, so considering them as a viable alternative is a moot point.

The impermeability of asphalt means that you’ll need to use either sloping and slot drains, trench drains, and/or off-site storage basins to manage the flow of runoff stormwater. This adds to the cost and timeline of a tractor-trailer parking lot installation project immensely, and the piping required to manage stormwater will need maintenance occasionally, too.

Concrete

Concrete is another paving material that is used in a tractor without trailer parking lot design. It’s less common than asphalt and rarely used in lots designed to house due to concrete’s higher installation costs.

Hot weather can make asphalt sticky and make an asphalt lot scorching hot thanks to the heat island effect. Concrete, on the other hand, becomes very fragile in cold weather and can easily crack, especially if the foundation is uneven or water damage has already taken a toll on the lot.

A tractor-trailer parking design made from concrete generally has the same pros and cons as asphalt except that one is vulnerable to hot weather, while the other is vulnerable to cold. Concrete is also known to be more expensive than asphalt and can take longer to install thanks to the drying times and multiple coats required during installation.

Permeable Pavement

Another option for you when creating a tractor-trailer parking lot design is to use permeable pavement. Permeable pavement with the ability to support tractor-trailers has just recently been invented by companies like TRUEGRID and others, so there isn’t as much of a precedent for it yet.

However, in time we can expect this material to become the standard for tractor-trailer parking lots because of its positive characteristics. For starters, TRUEGRID PRO PLUS pavers are literally durable enough to handle H20 and HS20 loading…anything you will see on the road TRUEGRID can handle.

So, it goes without saying that they can handle the stress and pressure of everyday tractor-trailers as well. They will last at least 25 years before needing replacement, in fact. And that’s with almost no maintenance required.

TRUEGRID PRO PLUS pavers are also 100%-permeable, further lessening the cost of installation by eliminating the need for additional drainage systems and maintenance on said drainage systems.

They achieve this level of permeability by using gravel-filled pavers over a gravel subsurface of about 12 inches deep for tractor trailer traffic. This allows the pavers to drain stormwater at an incredibly high rate and renders them virtually invulnerable to flooding or water damage.

Let TRUEGRID Handle Your Tractor Trailer Parking Lot Paving Needs

When it comes to the cons of TRUEGRID PRO PLUS pavers for tractor-trailer parking lots, there really are none. The finished product looks different than asphalt or concrete but still appears clean-cut and professional, with many even preferring it to traditional pavement. Besides that, TRUEGRID permeable pavers outperform asphalt and concrete in every other meaningful metric for tractor-trailer parking lots.

Don’t saddle yourself with a commitment to costly maintenance and additional drainage systems by building a tractor-trailer parking lot from asphalt or concrete. If you want the best solution for your trucks and your wallet, call TRUEGRID today to link up with a pavement professional who can get you started.