[Posted on August 26th, 2015 by: Barry Stiles]

Asphalt and concrete are by far the two most common kinds of commercial paving used on company parking lots and access roads, but they do not come without their problems. Asphalt is popular because it is cheaper to install than concrete, but its maintenance needs are almost constant. Concrete is very expensive to lay down and needs fewer repairs than asphalt, but the repairs it does need tend to be quite costly.

Despite these and other limitations, businesses typically choose concrete or asphalt pavement because the only other option is gravel, which erodes, dusts up, sinks down, and gets muddy. The only advantage, in fact, that gravel seems to offer is that it is the cheapest option available. But what if there were a way to take advantage of the low cost of gravel while avoiding its shortcomings? In that case, it would become, in many situations, the very best choice for commercial pavement.

And here it is:

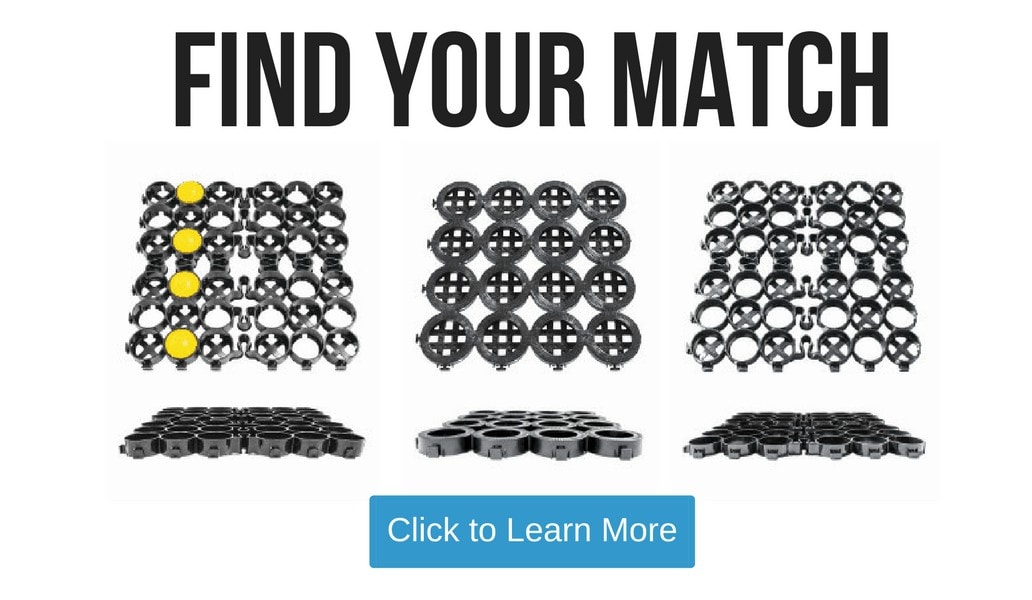

TRUEGRID pavers are a relatively new, innovative solution to many commercial paving problems. These durable plastic grids are installed above a drainage substrate and then filled in with an aggregate of your choice. Each rectangular piece is made up of numerous circular grid-sections, which are tied together by horseshoe-shaped connecting flex links for added strength. Rain and runoff water simply seep through the permeable pavement and disappear, while the grids hold the gravel in place and stand up against heavy pressure bearing down on them.

Some of the most important benefits of the TRUEGRID system are as follows:

- TRUEGRID pavers are cost-effective: The installation costs of this product is a third to a half that of asphalt or concrete, and it has virtually no maintenance costs. Because the plastic grids prevent gravel from wandering out of place or eroding away, there is less resurfacing to be done than with ordinary gravel driveways and parking lots.

- The pavement is 98% permeable: This high permeability prevents puddling, mud zones, and wash-outs. The substrate type and the fill depth can also be made more or less permeable, as needed, to meet local code requirements. Furthermore, land usage is greatly increased because the retention or detention structures are built right into the pavement’s sub-base.

- The load capacity is extremely great: TRUEGRID plastic reinforcements can bear 6,880 psi while still empty, and much more pressure once filled in with gravel. 85,000 + lb gravel trucks can drive on the grid with now problem prior to filling the grid with aggregate to speed the installation process. Weather will not significantly affect its ability to handle heavy loads. Its great strength makes it a first choice for semi-tractor parking lots, heavy equipment storage areas, and high-traffic access lanes.

- Vehicle wear and tear is reduced: Gravel-filled pavers produce much less strain on tires and axles while turning or maneuvering, and this will, over the course of time, translate into reduced vehicle maintenance needs.

- Gravel is kept firmly in place: Webbing often fails to keep gravel in its place, and concrete borders are expensive and still allow ruts to develop. TRUEGRID permeable pavers, however, prevent gravel spreading, stop rutting, and minimize dust-ups.

- It stays cool in the summer: Unlike asphalt and concrete, plastic-gridded gravel does not suffer from the “heat island effect.” You will not feel waves of heat rising off it nor feel it turn hot due to absorption of the summer heat.

- It does not deteriorate in the winter: The freeze/thaw cycle damages concrete and asphalt every winter, but gravel and grids are barely affected. Rock salt, which causes cracking in other pavements, will not damage a TRUEGRID system.

- TRUEGRID is the “greenest” commercial pavement: The pavers are made from 100% recycled plastic, and the sub-base drainage structure is formed from recycled concrete. Second, dirt can be used as a filler instead of gravel and grass grown on top of the pavement. Grassy parking areas often work well for overflow parking, fire lanes, golf cart paths, and more. They are certainly the most natural looking option. Finally, TRUEGRID pavers’ impact on the environment is low enough that it qualifies for LEED points, which can sometimes help sell properties to “green-conscious” land buyers.

- The TRUEGRID system puts safety first: These products are fully ADA compliant, and the grids make the gravel much less skid-prone than regular gravel because of the stability and friction they create.

- No re-striping will ever be needed: Parking space/lane markers lock into circular grid holes and can be moved fairly easily at a later date. You will not need to re-stripe, and you can re-arrange the space divisions as needed.

- The finished pavement is aesthetically pleasing: While beauty is in the eye of the beholder, most customers are enjoy the natural aesthetic of TRUEGRID pavements. Gravel fits well into a country setting, and the right colors of aggregate can complement nearby brick or stone structures in small towns. High-end retailers, even in the big cities, can do well by using gravel with attractive colors, textures, and sizes.

Using crushed gravel, or “self-binding gravel,” composed of a mix of larger particles and smaller ones (“fines”), helps to keep gravel from quickly deteriorating. A 20 to 60 year life cycle, equal or better than concrete and longer than asphalt is expected for a gravel filled TRUEGRID surface.

TRUEGRID is a Houston-based company that alone produces the commercial pavement system mentioned above. It offers nationwide shipping, and further information can be learned about its products by visiting their website and/or filling out an online information request form.

Sources:

www.angieslist.com/articles/pros-and-cons-asphalt-vs-concrete-driveway.htm

www.drivewayexpert.co.uk/advantages-disadvantages-gravel-driveways.html

www.landscaping.about.com/od/drivewaysandwalkways1/f/gravel_driveway.htm