WHY ARE POROUS PAVERS PREFERABLE TO CONCRETE OR ASPHALT?

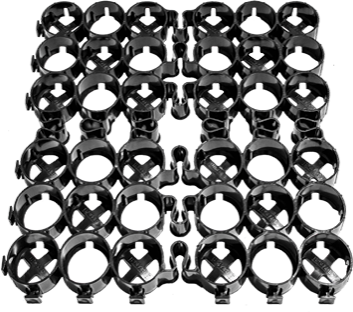

For providing exceptional environmental benefit, TRUEGRID porous pavers are beyond compare. Our pavers help prevent flooding or pooling of storm water, unlike concrete or asphalt. TRUEGRID pavers can be filled with grass or gravel for a stabilized parking surface while our patented design has flex joints that keep the grid surface from cracking or forming potholes found in concrete and asphalt installations. Our TRUEGRID paver surface dissipates heat and stays cool, unlike concrete and asphalt which raise local temperatures dramatically, contributing to the heat island effect. Using gravel or grass for a natural appearance, our TRUEGRID pervious pavers provide significantly higher compressive strengths and won’t become malleable in the heat like hot asphalt will. While conventional asphalt and concrete paved surfaces create storm water runoff that contributes to water pollution, the TRUEGRID system allows for bioremediation in its design allowing water to pass through the permeable surface and the aggregate sub-base to the earth below, cleaning pollutants naturally in the process. Additionally, our TRUEGRID paver installation is always a lower cost than concrete installations and is very competitive with asphalt, especially when more drainage is necessary. For more information on how you can use TRUEGRID in your project, please feel free to contact our experts at the number above.

HOW DO POROUS PAVERS HELP PREVENT STORM WATER RUNOFF?

With 98% porosity providing fast storm water drainage, TRUEGRID pavers help prevent runoff as rainwater passes through the paver grid and aggregate that fills it into the voids in the sub-base. Our sub-base design typically consists of 4-6″ of #57 angular rock, recycled road base or crushed granite, with a sandy loam mix for grass installations. This sub-base in addition to the 2“ deep grid with fill material provides a large retention area that stores and then slowly releases water naturally without producing runoff.Our TRUEGRID parking lots, roadways or developments that are properly designed often have less runoff after the grid system is installed than it did before the installation. If you’d like more information on TRUEGRID’s green properties, click on the Environment tab above.

CAN POROUS PAVERS BEAR THE WEIGHT OF A COMMERCIAL PARKING LOT?

Our TRUEGRID permeable pavement has an exceptional tolerance for abuse, with a compression strength of over 6800 psi before they’re even filled! This means gravel-filled trucks can be driven on the unfilled grid top to spread rock during the construction process. Our TRUEGRID pavers used in a lot has an expected lifespan of up to 25 to 20 years depending on your traffic type and volume. TRUEGRID is the world’s toughest permeable paver. Compared to any interlocking porous paver system on the market, rock filled TRUEGRID has the highest compression strength and durability. Unlike concrete or asphalt paving systems, TRUEGRID won’t crack or develop potholes when installed correctly. For further information on our specifications and technical drawings of our installations, please click on the Engineers & Architects tab above

Testimonials

Super easy to install! Love the results! I will send photos!

We were worried about using asphalt for this truck lot in the hot South Texas sun. The grid replaced 8” asphalt, the truckers like it because it’s cool and it’s easier on their tires. The client saved 6 figures and we won the bid